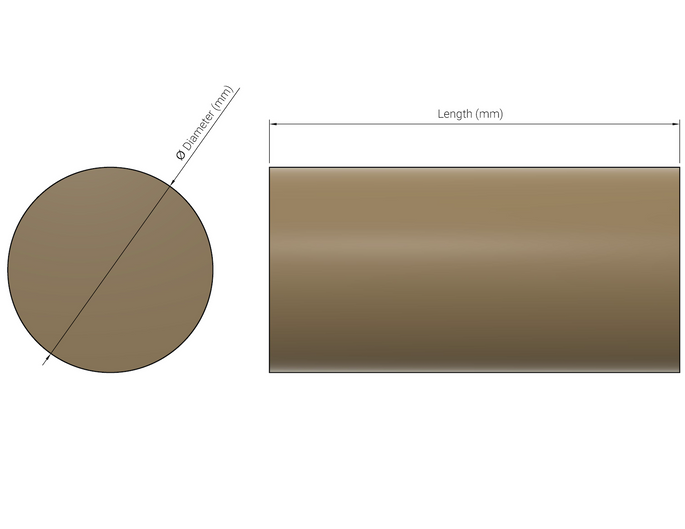

PEEK GF30 Rod

PEEK GF30 Rod

Couldn't load pickup availability

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom right of your screen.

Email: sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Material: PEEK GF30

Measurement System: Metric

Colour: Natural/Beige

Continuous use temperature: 260°C/500°F

Flammability: UL94 V-0

PEEK GF30 Rod conform to the following Standards/Norms:

PEEK GF30 rods are manufactured via extrusion from raw Polyetheretherketone reinforced with 30% glass fiber.

We provide cutting and precision grinding services on request, please get in touch for more information.

PEEK GF30 rods possess enhanced mechanical properties compared to unfilled PEEK, making them suitable for demanding applications in various industries:

Key Properties:

High strength and stiffness: The glass fiber reinforcement significantly improves the mechanical properties of PEEK, providing high tensile and flexural strength, as well as improved resistance to deformation.

Excellent chemical resistance: PEEK GF30 exhibits resistance to a wide range of chemicals, including acids, bases, solvents, and hydrocarbons.

High temperature resistance: PEEK GF30 has a high glass transition temperature (Tg) of around 143°C to 150°C, allowing it to maintain its properties at elevated temperatures.

Excellent wear and friction properties: PEEK GF30 offers low friction coefficients and excellent wear resistance, making it suitable for applications involving moving parts.

Electrical properties: PEEK GF30 has good electrical insulating properties and is often used in electrical connectors and insulators.

Dimensional stability: The glass fiber reinforcement helps minimize dimensional changes due to temperature variations, making PEEK GF30 suitable for applications with tight tolerances.

Machinability:

PEEK GF30 is a tough and strong material, with good machinability. It has a high melting point, and therefore does not clog the cutting tools as with nylon or similar polymer materials.

Machining processes such as milling, turning, drilling, and threading are typically used to processes PEEK GF30 rods.

Cutting tools made from carbide or high-speed steel are commonly utilised, with careful consideration given to tool geometry and cutting parameters.

Adequate cooling and lubrication during machining help maintain dimensional accuracy and extend tool life.

Industries/Applications:

Aerospace: PEEK GF30 is used in aircraft components such as structural parts, fasteners, bearings, and electrical connectors.

Automotive: Applications include bushings, gears, seals, and electrical connectors in engines, transmissions, and electrical systems.

Oil and Gas: PEEK GF30 is employed in downhole tools, seals, and connectors due to its chemical resistance and high strength in aggressive environments.

Medical: PEEK GF30 is used in orthopaedic implants, surgical instruments, dental instruments, and medical device components due to its biocompatibility and sterilization resistance.

Electronics: PEEK GF30 finds use in electrical connectors, insulators, and circuit boards due to its electrical properties and dimensional stability.

Chemical processing: PEEK GF30 is employed in pump components, valves, seals, and other chemical processing equipment due to its resistance to chemicals and high temperatures.

For more information on the specific properties of PEEK GF30 rod, please see our datasheet below.

The PEEK GF30 data sheet is available as a PDF to download below.

Return components within 90 days for a full refund. Please see returns terms and conditions for further information.

Polyether Ether Ketone GF30 (PEEK GF30) - 30% Glass Fibre Reinforced Datasheet

Follow the link below to view our PEEK GF30 data sheet. This includes properties such as mechanical, electrical, thermal and chemical resistance.

PEEK GF30 Key Properties

Why Choose High Performance Polymer?

-

50,000+ Fasteners In stock

No long lead times. We have a large range of PEEK fasteners available for express delivery (Dispatched the same day if ordered before 3PM Monday-Thursday).

Fasteners not available for express delivery will display the expected delivery date above the 'add to cart' button.

Manufacturer Direct DistributorWe are a manufacturer direct distributor, this allows us to ensure highly competitive prices and keep our shelves stocked. All of our products are manufactured to the highest standards and exhibit exceptional characteristics.

ISO9001 CertifiedCertified through Quality Veritas. High Performance Polymer conforms to the ISO9001 quality management system. Certificates available on request.

-

Material Certificates

We provide full material traceability and can provide certification confirming material data and batch number, which can be traced back to the manufacturer.

Certificate Of ConformityWe also provide a certificate of conformity on request, confirming the product manufacturing standard and material.