Polyetherimide (PEI) Compression Springs

Polyetherimide (PEI) Compression Springs

Couldn't load pickup availability

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom right of your screen.

Email: sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Material: PEI/Ultem

Measurement System: Metric

Colour: Natural/Beige

Max Temperature: 170°C/340°F

Flame Resistance: UL94 V-0

Polyetherimide (PEI) Compression Springs conform to the following Standards/Norms:

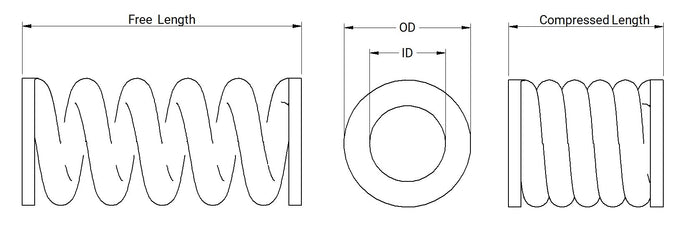

Polyetherimide (PEI) Compression Springs, available in sizes ranging from Inner Diameter (ID) of 1mm to 20.5mm, Outer Diameter (OD) of 2mm to 25mm, and Free Lengths of 8mm to 50mm, are made from Polyetherimide, a high-performance thermoplastic known for its exceptional mechanical properties, thermal stability, and chemical resistance. PEI offers high tensile and compressive strength, excellent dimensional stability, and outstanding resistance to a wide range of chemicals. These properties make PEI Compression Springs ideal for demanding applications that require reliable performance under various loads and environmental conditions.

Sizes (see full table below) :

Inner Diameter (mm) - 1 to 20.5mm

Outer Diameter (mm) - 2 to 25mm

Free Length (mm) - 8 to 50mm

Advantages of Using Polyetherimide (PEI) Compression Springs:

High Mechanical Strength: PEI provides excellent tensile and compressive strength, ensuring robust performance under heavy loads and high-stress conditions.

Thermal Stability: PEI maintains its mechanical properties over a wide temperature range, making these springs suitable for both high-temperature and cryogenic environments.

Chemical Resistance: PEI is resistant to a broad spectrum of chemicals, including acids, bases, and solvents, ensuring durability in corrosive environments.

Dimensional Stability: The material offers excellent dimensional stability, ensuring the springs maintain their shape and performance over time, even in precise applications.

Low Creep and Long-Term Performance: PEI exhibits low creep, meaning it maintains its mechanical properties and shape over long periods under continuous stress.

Flame Retardant: PEI has inherent flame retardant properties, making it suitable for applications requiring fire resistance.

Electrical Insulation: PEI provides excellent electrical insulating properties, making these springs ideal for electronic and electrical applications.

Specific Applications of Polyetherimide (PEI) Compression Springs:

Aerospace:

Used in aircraft and spacecraft systems where high-strength, lightweight, and thermally stable components are critical.

Suitable for environments with extreme temperatures and exposure to various chemicals.

Automotive Industry:

Applied in automotive components that require high mechanical strength, thermal stability, and chemical resistance, such as in engine and transmission systems.

Medical Devices:

Utilised in medical instruments and diagnostic equipment where high precision, biocompatibility, and resistance to sterilisation processes are essential.

Industrial Machinery:

Employed in machinery and equipment that require robust components capable of withstanding high loads and harsh chemical environments.

Electronics and Electrical Equipment:

Used in the assembly of electronic devices and enclosures, where the springs' electrical insulation properties and thermal stability are beneficial.

Ideal for securing and positioning delicate components.

Chemical Processing:

Applied in securing components in chemical processing plants, where resistance to aggressive chemicals and high temperatures is crucial.

Ideal for use in pumps, valves, and reactors.

Telecommunications:

Utilised in devices and systems where flame retardancy, electrical insulation, and long-term performance are critical.

Polyetherimide (PEI) Compression Springs, with Inner Diameters from 1mm to 20.5mm, Outer Diameters from 2mm to 25mm, and Free Lengths from 8mm to 50mm, offer a high-performance solution made from Polyetherimide. These springs are known for their high mechanical strength, thermal stability, chemical resistance, and excellent dimensional stability. Ideal for a variety of demanding applications across aerospace, automotive, medical devices, industrial machinery, electronics, chemical processing, and telecommunications industries, PEI compression springs provide reliable and long-lasting performance in critical environments.

The PEI/Ultem data sheet is available as a PDF to download below.

Return components within 90 days for a full refund. Please see returns terms and conditions for further information.

| Inner Diameter (mm) | Outside Diameter (mm) | Free Length (mm) | Solid Height (mm) | Spring Rate (mm) |

| 1 | 2 | 8 | 5 | 0.57 |

| 2.2 | 3 | 20 | 10.70 | 0.07 |

| 4 | 8 | 20 | 12.50 | 1.59 |

| 4 | 8 | 30 | 18 | 0.80 |

| 4 | 8 | 40 | 24 | 0.56 |

| 4 | 8 | 50 | 30 | 0.56 |

| 5 | 9 | 20 | 12 | 0.89 |

| 5 | 9 | 30 | 18 | 0.67 |

| 5 | 9 | 40 | 24 | 0.48 |

| 5 | 9 | 50 | 30 | 0.47 |

| 6 | 10 | 30 | 18 | 0.97 |

| 6 | 10 | 40 | 24 | 0.73 |

| 6 | 10 | 50 | 31 | 0.87 |

| 6 | 12 | 25 | 14.5 | 4.10 |

| 7.5 | 10 | 17.2 | 6.5 | 0.53 |

| 8 | 12 | 20 | 12 | 0.48 |

| 8 | 12 | 30 | 18 | 0.35 |

| 8 | 12 | 40 | 24 | 0.35 |

| 8 | 12 | 50 | 30 | 1.05 |

| 20.5 | 25 | 36 | 16 | 0.15 |

Dimension Table

Dimensions for Polyetherimide (PEI) Compression Springs in all available sizes are shown according to the product drawing above.

PEI/Ultem Key Properties

Why Choose High Performance Polymer?

-

50,000+ Fasteners In stock

No long lead times. We have a large range of PEEK fasteners available for express delivery (Dispatched the same day if ordered before 3PM Monday-Thursday).

Fasteners not available for express delivery will display the expected delivery date above the 'add to cart' button.

Manufacturer Direct DistributorWe are a manufacturer direct distributor, this allows us to ensure highly competitive prices and keep our shelves stocked. All of our products are manufactured to the highest standards and exhibit exceptional characteristics.

ISO9001 CertifiedCertified through Quality Veritas. High Performance Polymer conforms to the ISO9001 quality management system. Certificates available on request.

-

Material Certificates

We provide full material traceability and can provide certification confirming material data and batch number, which can be traced back to the manufacturer.

Certificate Of ConformityWe also provide a certificate of conformity on request, confirming the product manufacturing standard and material.