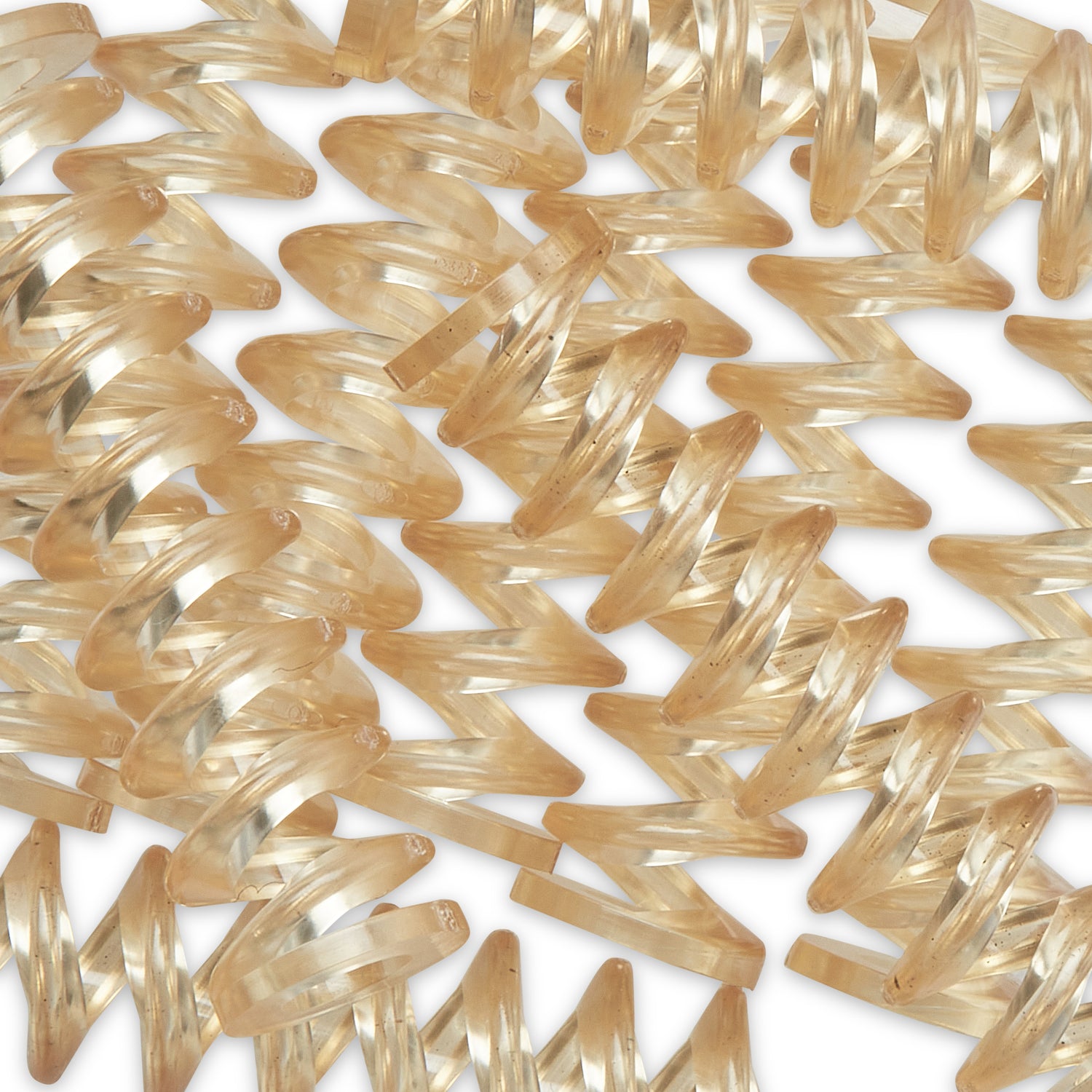

10 produits

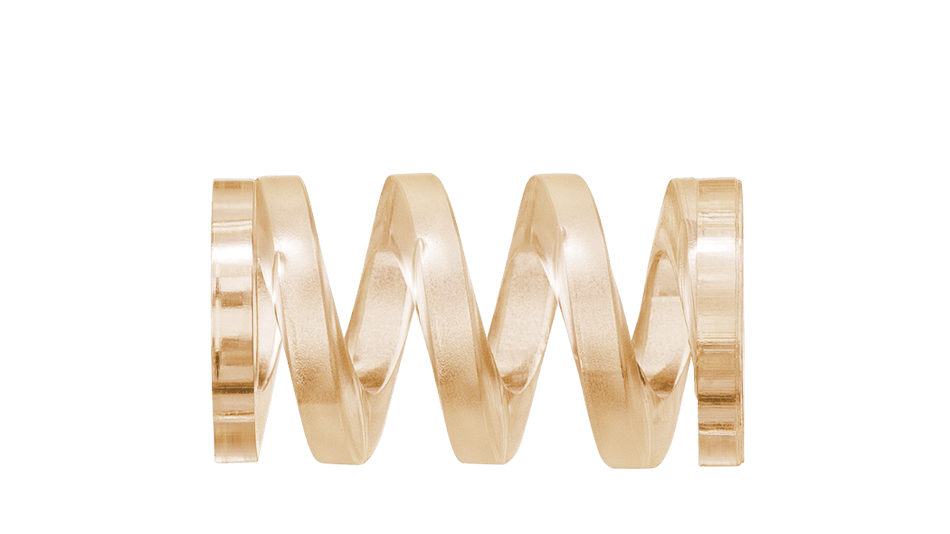

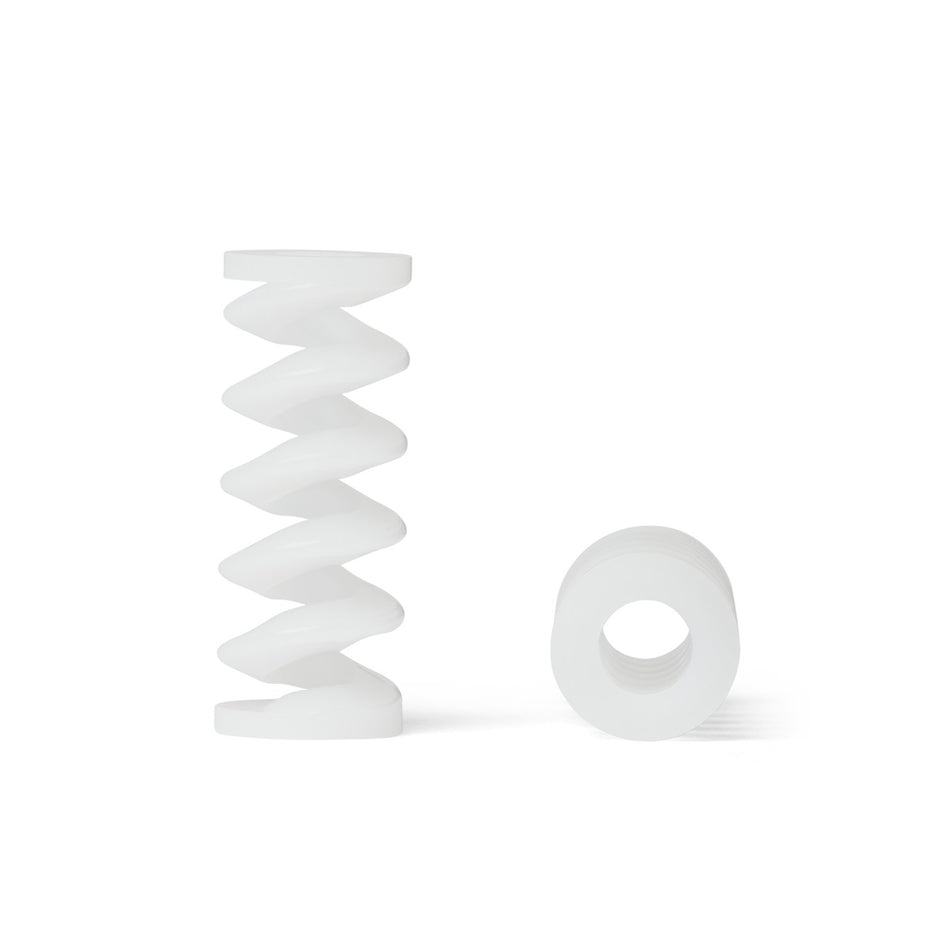

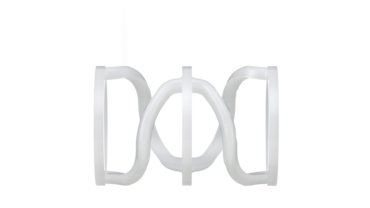

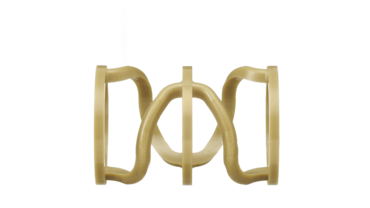

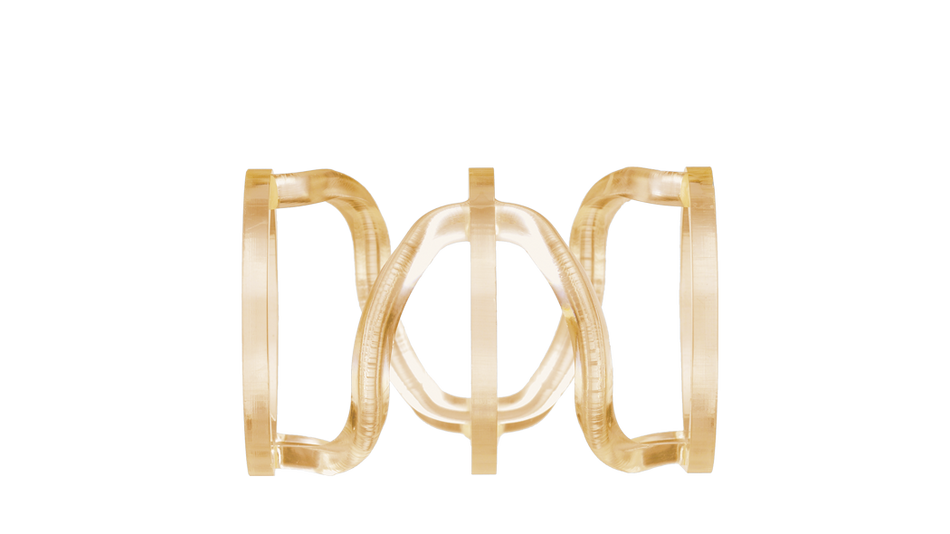

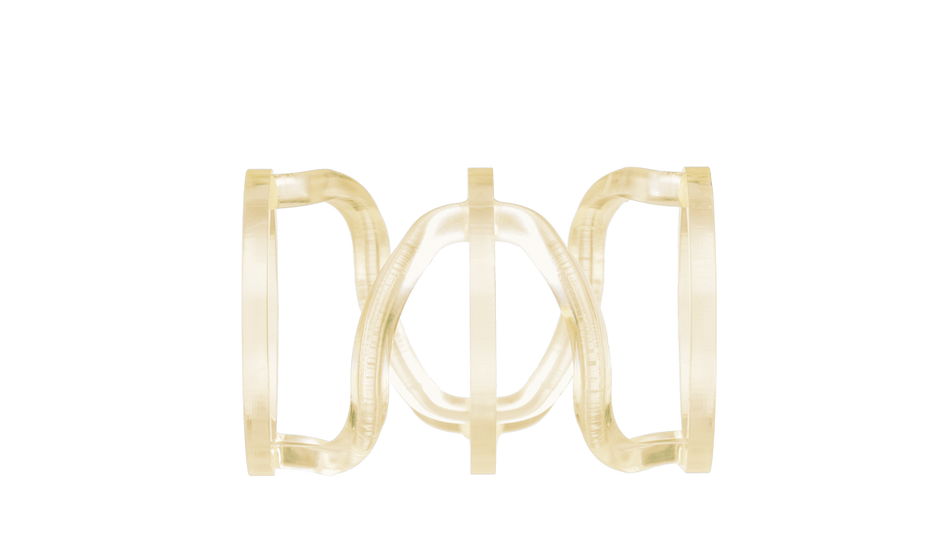

Industry applications for plastic springs

What are the benefits of using plastic for springs?

Les vis en plastique offrent des avantages uniques que les vis métalliques ne peuvent pas offrir. Elles sont très résistantes à la corrosion, ce qui les rend idéales pour une utilisation dans des environnements chimiques difficiles où les vis métalliques se dégraderaient. Leur nature légère réduit le poids total des assemblages, ce qui est crucial dans des secteurs comme l'aérospatiale et l'automobile, où les économies de poids se traduisent par de meilleures performances et une meilleure efficacité énergétique. Les vis en plastique offrent également une excellente isolation électrique, évitant les courts-circuits dans les appareils électroniques. De plus, elles ont des rapports résistance/poids élevés, sont non magnétiques et peuvent résister à une large plage de températures. Ces propriétés rendent les vis en plastique essentielles pour les applications nécessitant une durabilité, une fiabilité et des caractéristiques de performance spécialisées que les vis métalliques ne peuvent pas offrir.