Ressorts de compression en polyphénylsulfone (PPSU)

Ressorts de compression en polyphénylsulfone (PPSU)

Want it by XYZ?

Besoin d'aide?

Notre équipe est toujours heureuse de vous aider!

Chat en direct : disponible en bas à droite de votre écran.

E-mail:

sales@highperformancepolymer.com

Téléphone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

Matériau :

Système de mesure : métrique

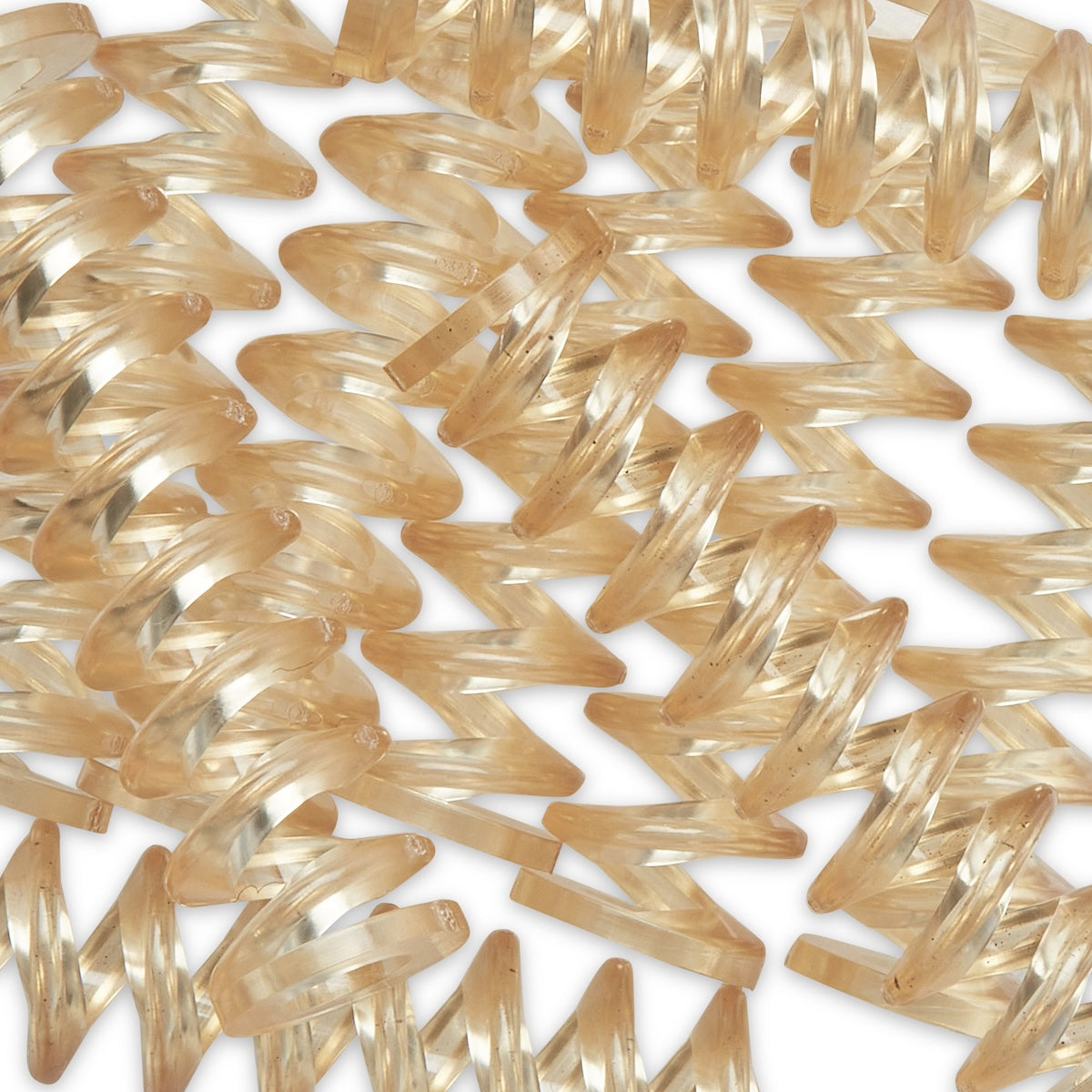

Couleur : Naturel/Beige

Ressorts de compression en polyphénylsulfone (PPSU) est conforme aux standards/normes suivants :

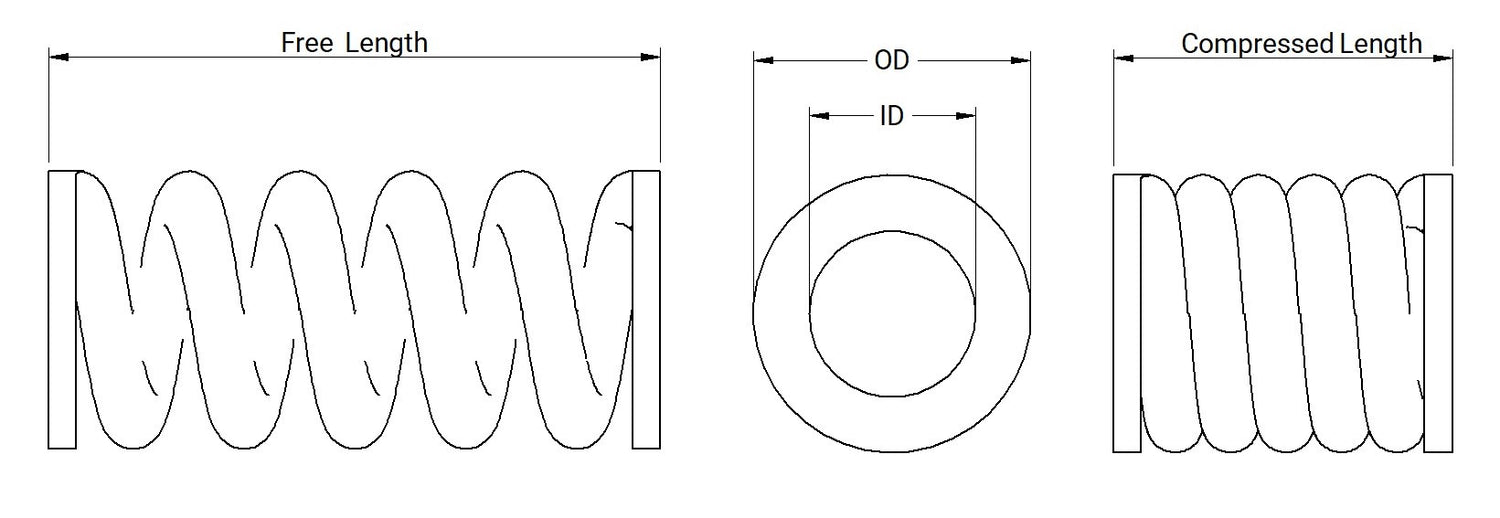

Les ressorts de compression en polyphénylsulfone (PPSU), disponibles dans des tailles allant du diamètre intérieur (DI) de 1 mm à 20,5 mm, du diamètre extérieur (DE) de 2 mm à 25 mm et des longueurs libres de 8 mm à 50 mm, sont fabriqués à partir de polyphénylsulfone, un thermoplastique haute performance connu pour sa ténacité exceptionnelle, sa stabilité thermique et sa résistance chimique. Le PPSU offre une excellente résistance aux chocs, une résistance élevée aux processus de stérilisation et une bonne stabilité hydrolytique, ce qui rend ces ressorts de compression idéaux pour les applications nécessitant une durabilité et des performances fiables dans des environnements exigeants.

Tailles (voir tableau complet ci-dessous) :

Diamètre intérieur (mm) - 1 à 20,5 mm

Diamètre extérieur (mm) - 2 à 25 mm

Longueur libre (mm) - 8 à 50 mm

Avantages de l'utilisation de ressorts de compression en polyphénylsulfone (PPSU) :

Haute résistance aux chocs : le PPSU offre une ténacité et une résistance aux chocs supérieures, garantissant durabilité et performances à long terme.

Stabilité thermique : Le matériau conserve ses propriétés mécaniques sur une large plage de températures, ce qui le rend adapté aux applications à haute température et cryogéniques.

Résistance chimique : le PPSU résiste à un large spectre de produits chimiques, notamment les acides, les bases et les solvants, garantissant ainsi sa durabilité dans les environnements corrosifs.

Stabilité hydrolytique : Le matériau résiste à la dégradation en présence d’eau, ce qui le rend adapté aux applications impliquant une exposition fréquente à l’humidité.

Résistance à la stérilisation : le PPSU peut résister à des processus de stérilisation répétés, ce qui le rend idéal pour les applications médicales et alimentaires.

Biocompatibilité : Le matériau est biocompatible, ce qui le rend adapté à une utilisation dans les dispositifs et équipements médicaux.

Stabilité dimensionnelle : le PPSU conserve sa forme et ses propriétés mécaniques au fil du temps, garantissant des performances constantes dans des applications précises.

Applications spécifiques des ressorts de compression en polyphénylsulfone (PPSU) :

Dispositifs médicaux :

Utilisé dans les instruments médicaux et les équipements de diagnostic où la haute précision, la biocompatibilité et la résistance aux processus de stérilisation sont essentielles.

Idéal pour les composants qui nécessitent une action de ressort constante et une durabilité.

Transformation et emballage des aliments :

Appliqué dans les équipements de transformation des aliments et les machines d'emballage en raison de sa résistance chimique et de sa capacité à résister aux processus de stérilisation.

Aérospatial:

Utilisé dans les systèmes d'aéronefs et d'engins spatiaux où une résistance élevée, une stabilité thermique et une résistance aux chocs sont essentielles.

Industrie automobile :

Utilisé dans les composants automobiles qui nécessitent de la robustesse, une résistance chimique et la capacité de résister à des températures élevées, comme dans les systèmes de moteur et de transmission.

Machines industrielles :

Appliqué aux machines et équipements qui subissent des impacts fréquents et nécessitent des composants robustes pour maintenir l'intégrité opérationnelle.

Equipements électroniques et électriques :

Utilisé dans l'assemblage d'appareils et de boîtiers électroniques où les propriétés d'isolation électrique et la stabilité thermique des ressorts sont bénéfiques.

Plomberie et gestion des fluides :

Utilisé dans la plomberie et les systèmes de traitement des fluides en raison de sa stabilité hydrolytique et de sa résistance aux produits chimiques.

Les ressorts de compression en polyphénylsulfone (PPSU), avec des diamètres intérieurs de 1 mm à 20,5 mm, des diamètres extérieurs de 2 mm à 25 mm et des longueurs libres de 8 mm à 50 mm, offrent une solution robuste et fiable fabriquée à partir d'un thermoplastique haute performance. Ces ressorts sont idéaux pour diverses applications dans les secteurs des appareils médicaux, de la transformation des aliments, de l'aérospatiale, de l'automobile, des machines industrielles, de l'électronique et de la plomberie. La combinaison d'une résistance élevée aux chocs, d'une stabilité thermique, d'une résistance chimique et d'une stabilité hydrolytique garantit que les ressorts de compression en PPSU offrent des performances fiables et durables dans des environnements exigeants.

La fiche technique est disponible au format PDF à télécharger ci-dessous.

Retournez les composants dans les 90 jours pour un remboursement complet. Veuillez consulter les conditions générales de retour pour plus d'informations.

| Inner Diameter (mm) | Outside Diameter (mm) | Free Length (mm) | Solid Height (mm) | Spring Rate (mm) |

| 1 | 2 | 8 | 5 | 0.34 |

| 4 | 8 | 30 | 18 | 0.58 |

| 4 | 8 | 50 | 30 | 0.42 |

| 5 | 9 | 20 | 12 | 0.61 |

| 5 | 9 | 30 | 18 | 0.51 |

| 5 | 9 | 40 | 24 | 0.34 |

| 5 | 9 | 50 | 30 | 0.31 |

| 6 | 10 | 30 | 18 | 0.74 |

| 6 | 10 | 40 | 24 | 0.55 |

| 6 | 10 | 50 | 31 | 0.64 |

| 6 | 12 | 25 | 14.5 | 2.57 |

| 7.5 | 10 | 17.2 | 6.5 | 0.03 |

| 8 | 12 | 30 | 18 | 0.25 |

| 8 | 12 | 40 | 24 | 0.24 |

| 8 | 12 | 50 | 30 | 0.67 |

| 20.5 | 25 | 36 | 16 | 0.11 |

Tableau des dimensions

Les dimensions de Ressorts de compression en polyphénylsulfone (PPSU) dans toutes les tailles disponibles sont indiquées selon le dessin du produit ci-dessus.

Custom Manufacturing

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

Pourquoi choisir un polymère haute performance ?

-

Plus de 50 000 fixations en stock

Pas de longs délais. Nous avons une large gamme de fixations PEEK disponibles pour une livraison express (Expédié le jour même si commandé avant 15h du lundi au jeudi).

Les attaches non disponibles pour la livraison express afficheront la date de livraison prévue au-dessus du bouton "ajouter au panier".

Distributeur direct du fabricantNous sommes un distributeur direct du fabricant, cela nous permet d'assurer des prix très compétitifs et de garder nos étagères bien garnies. Tous nos produits sont fabriqués selon les normes les plus élevées et présentent des caractéristiques exceptionnelles.

Certifié ISO9001Certifié par Quality Veritas. Le polymère haute performance est conforme au système de gestion de la qualité ISO9001. Certificats disponibles sur demande.

-

Certificats de matériel

Nous fournissons une traçabilité complète des matériaux et pouvons fournir une certification confirmant les données des matériaux et le numéro de lot, qui peuvent être retracés jusqu'au fabricant.

Certificat de conformitéNous fournissons également un certificat de conformité sur demande, confirmant la norme de fabrication du produit et le matériau.