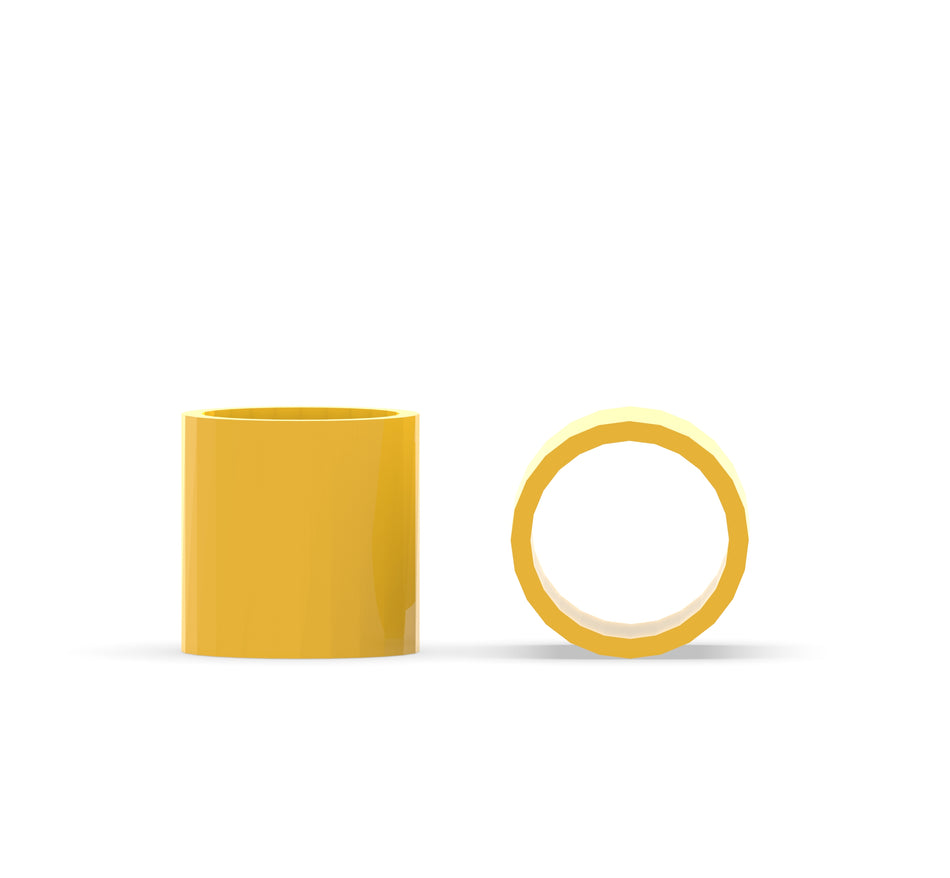

Thermoplastic Polyimide (TPI) Custom Manufactured Components

Besoin d'aide?

Notre équipe est toujours heureuse de vous aider!

Chat en direct : disponible en bas à droite de votre écran.

E-mail:

sales@highperformancepolymer.com

Téléphone: +44(0)1865 684080

All custom-manufactured products have a typical lead time of 3-4 weeks. However, please do contact us to get an exact quote.

Why choose Custom Manufacturing?

Custom manufacturing provides components built to your exact specifications - ensuring a precise fit, reliable performance, and full compatibility with your application. Unlike standard parts, custom solutions allow for the right material, geometry, and tolerances from the start. This is especially beneficial for large-scale projects where consistency across every unit is critical, helping to reduce errors, streamline production, and maintain high quality throughout.

-

CNC Machining

CNC machining offers precise, repeatable manufacturing for complex parts with tight tolerances. Ideal for high-performance polymers, it ensures accuracy, consistency, and a high-quality finish across both prototypes and production runs.

-

Injection Molding

Injection molding is a cost-effective solution for producing high volumes of complex polymer parts with excellent repeatability. It delivers consistent quality, tight tolerances, and efficient cycle times - ideal for large production runs where precision and uniformity are essential.

The Process