HPLC Fittings

HPLC fittings are components used in High-Performance Liquid Chromatography (HPLC) systems to establish secure connections between different parts of the chromatographic setup. They play a critical role in ensuring leak-free connections and efficient flow of the liquid throughout the system.

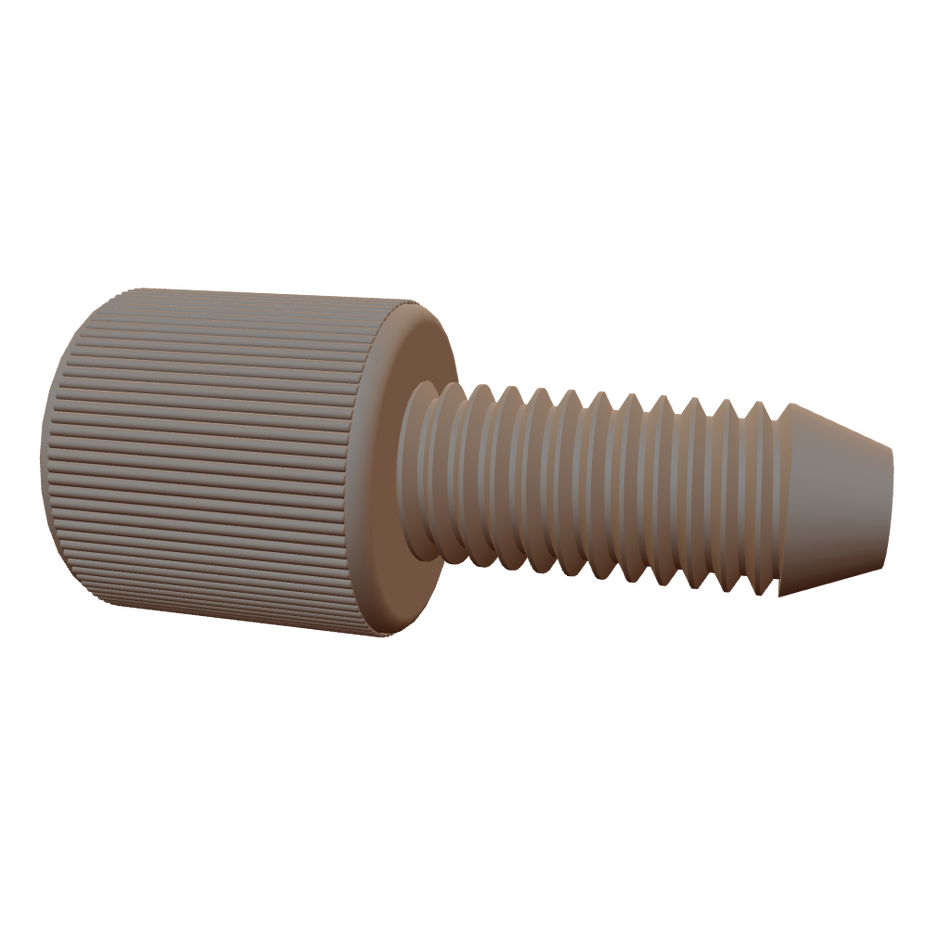

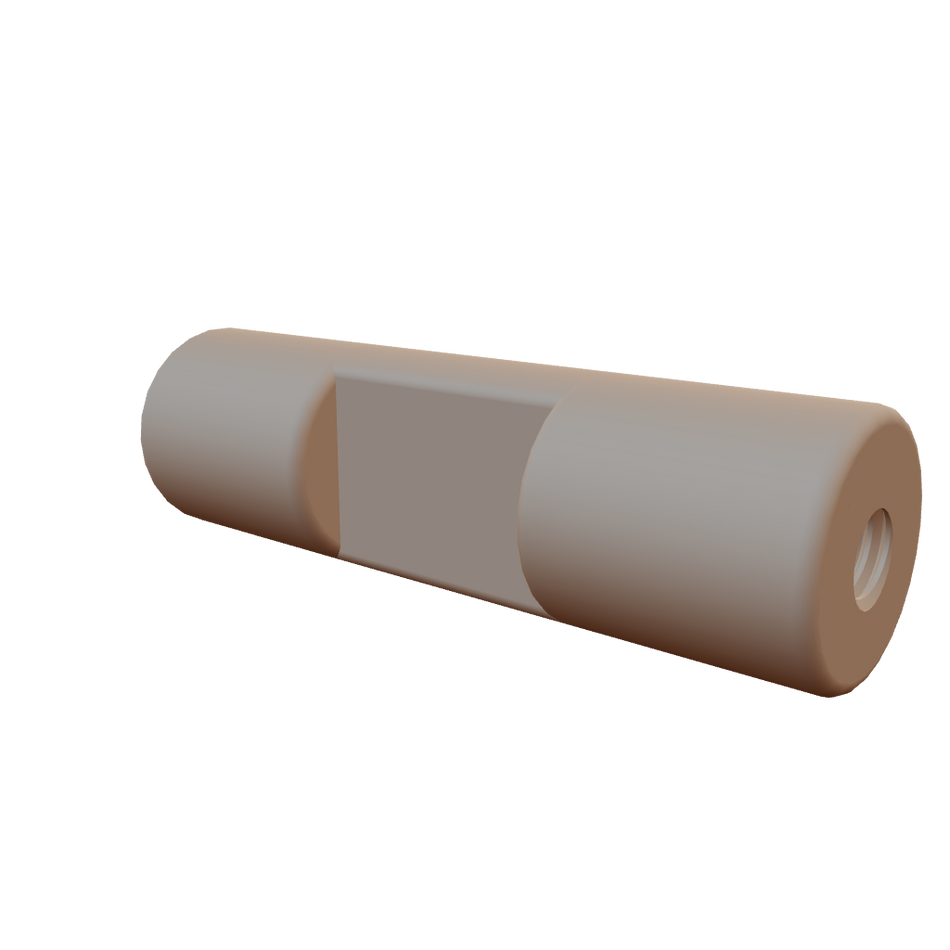

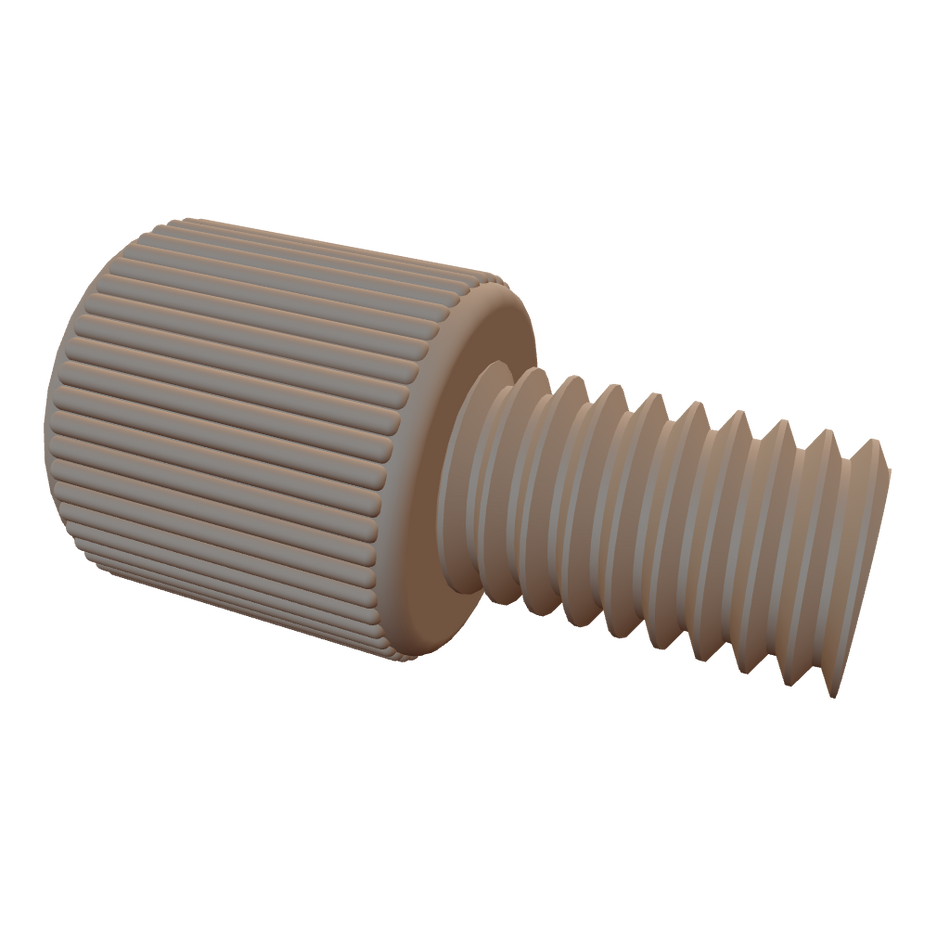

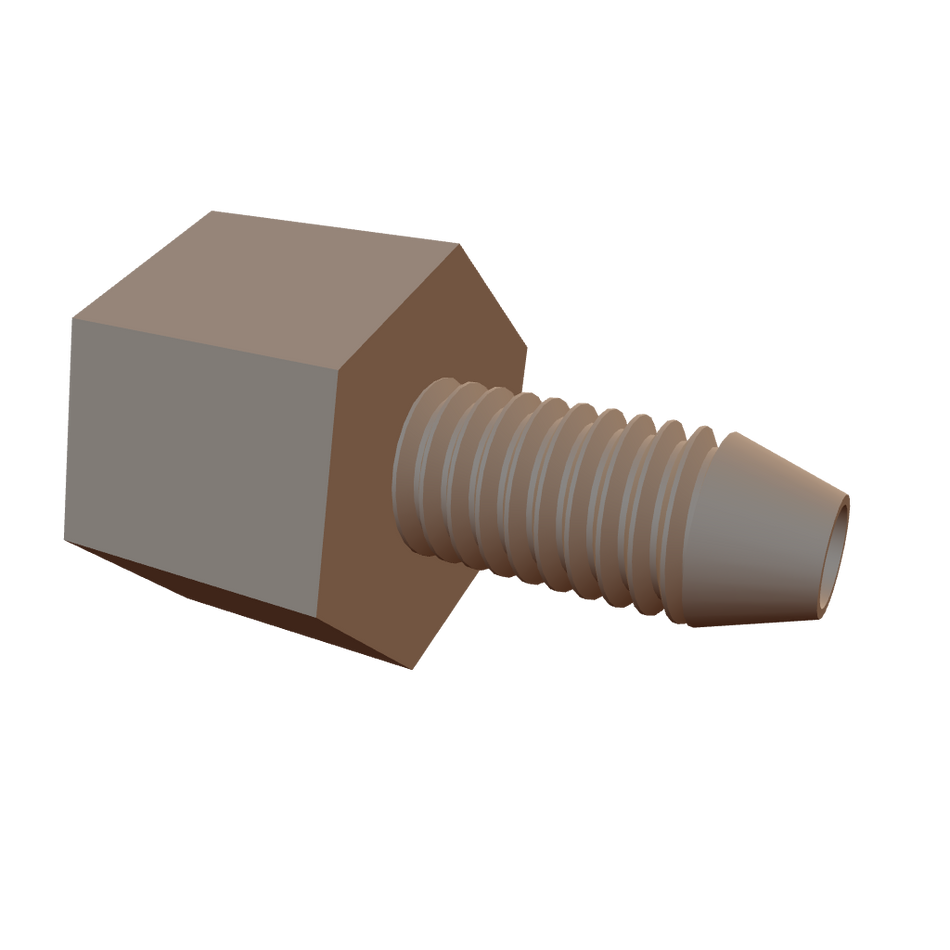

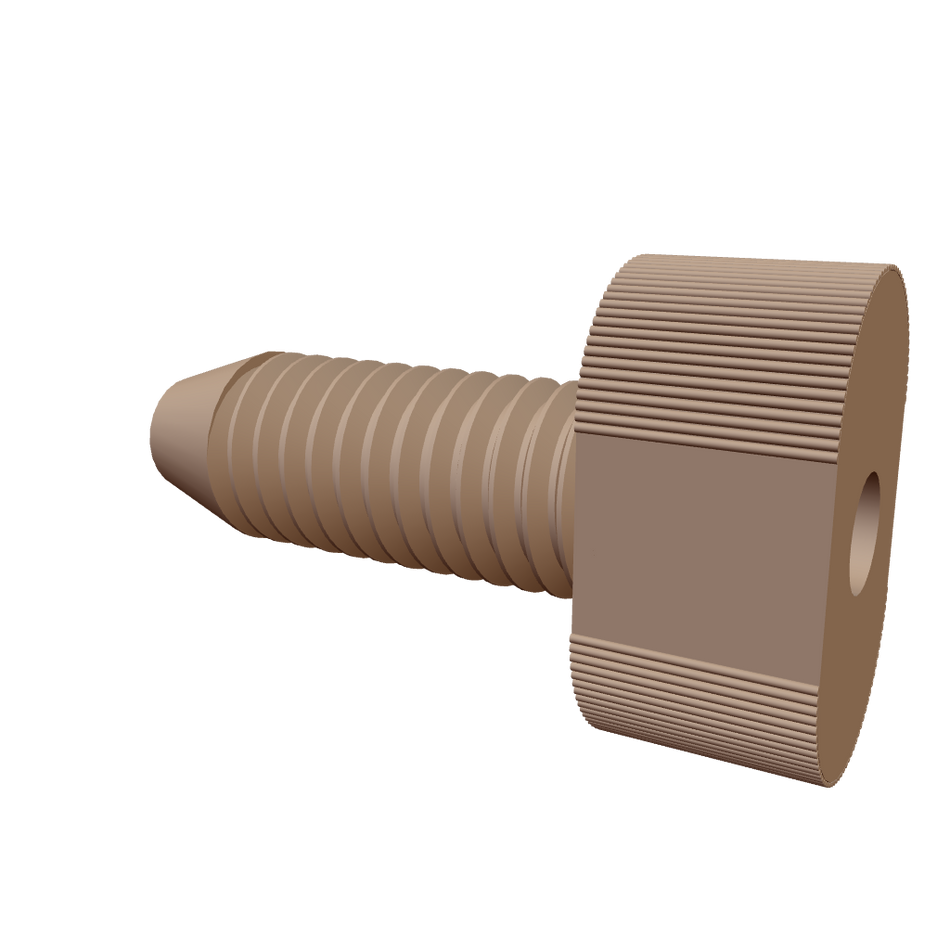

HPLC fittings come in various shapes and sizes, designed to accommodate the specific requirements of the HPLC system. Common types of fittings include ferrules, unions, adapters, connectors, and filters.

Ferrules are small rings that are placed around the tubing to create a secure seal. They are typically made of metal or polymeric materials. Unions are used to join two pieces of tubing together, ensuring a tight connection and preventing leaks. Adapters are employed to connect components with different connection types, allowing compatibility between different parts of the system. Connectors are used to secure connections between various components such as columns, detectors, injection valves, or pumps. Filters are often incorporated into the fittings to remove particulate matter or protect sensitive components from contamination.

Proper selection and installation of HPLC fittings are crucial to ensure the integrity and performance of the system. They should be compatible with the system and the solvents or samples being used. Tight connections are essential to prevent leaks, which can compromise the accuracy and reliability of the chromatographic analysis. Attention should also be paid to the size, shape, and compatibility of the fittings to ensure optimal flow and minimal dead volume.

Overall, HPLC fittings are integral components in HPLC systems, providing secure connections and facilitating the smooth flow of liquids throughout the system. Their proper selection, installation, and maintenance are essential for achieving accurate and reliable chromatographic results.