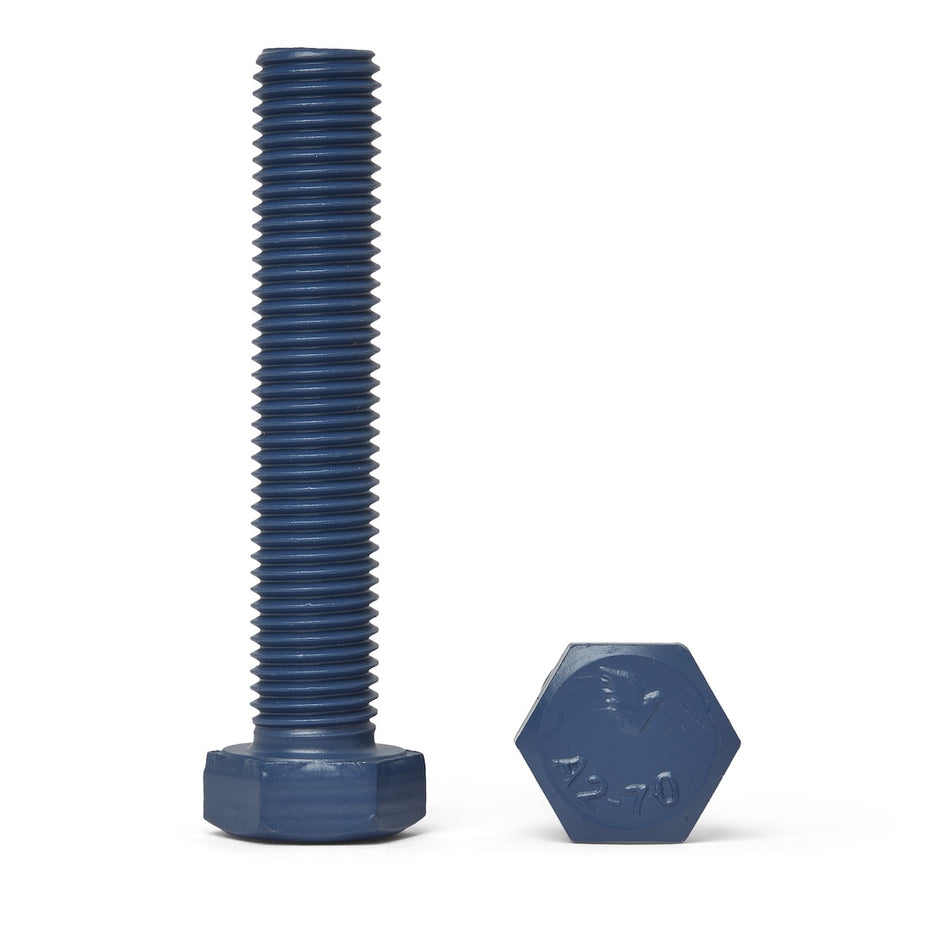

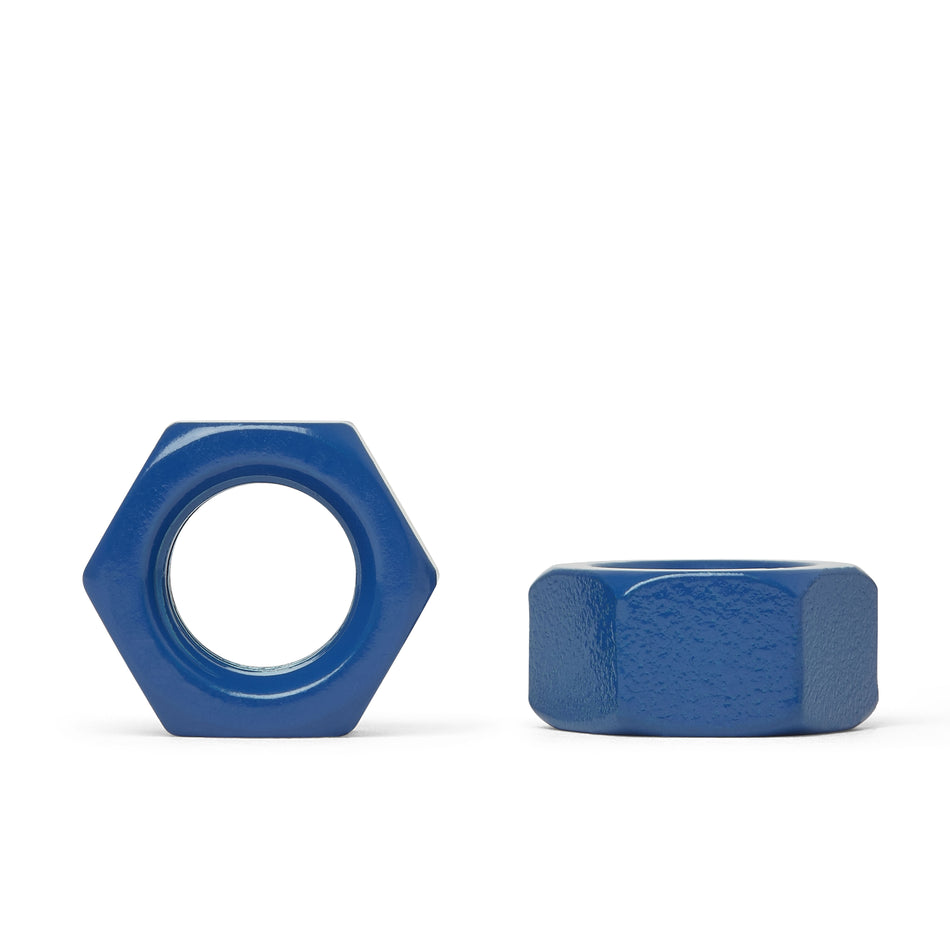

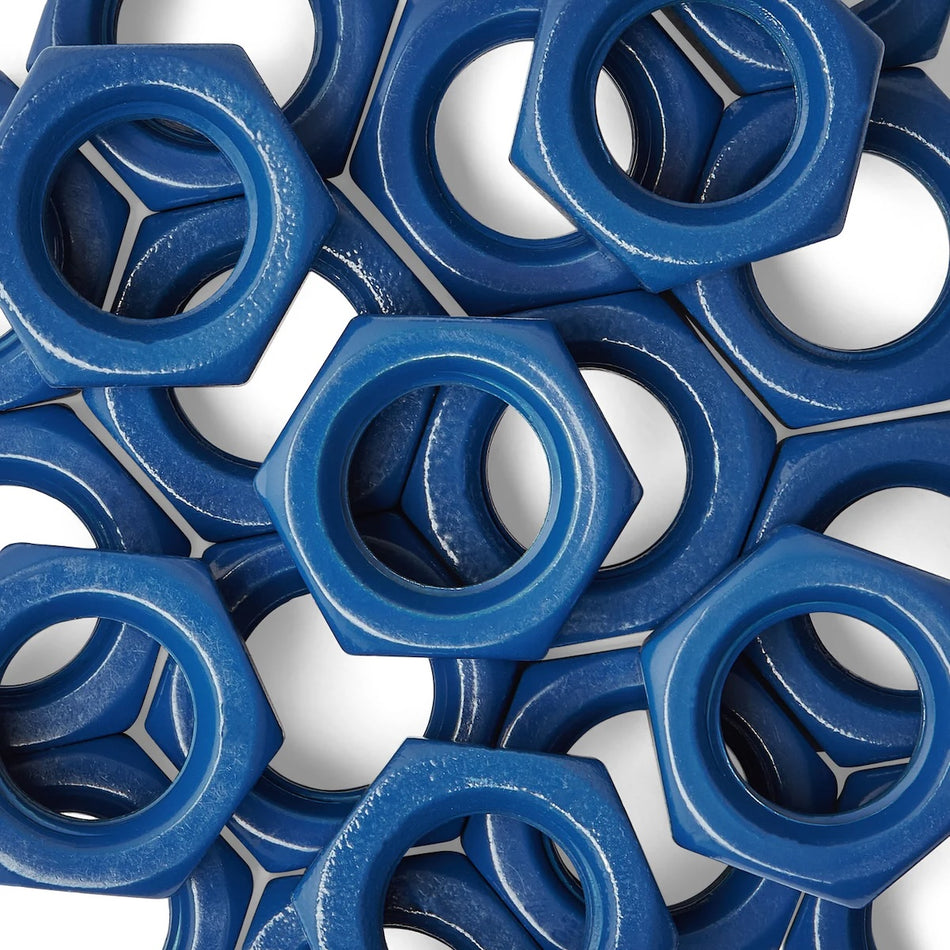

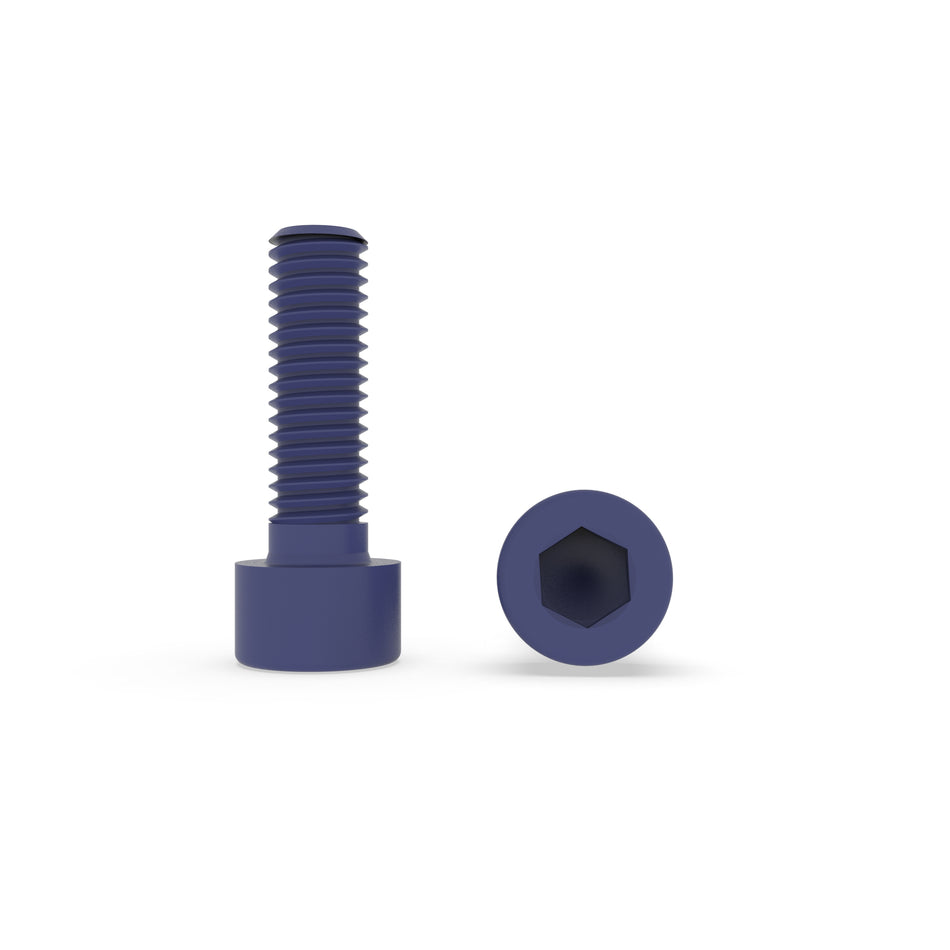

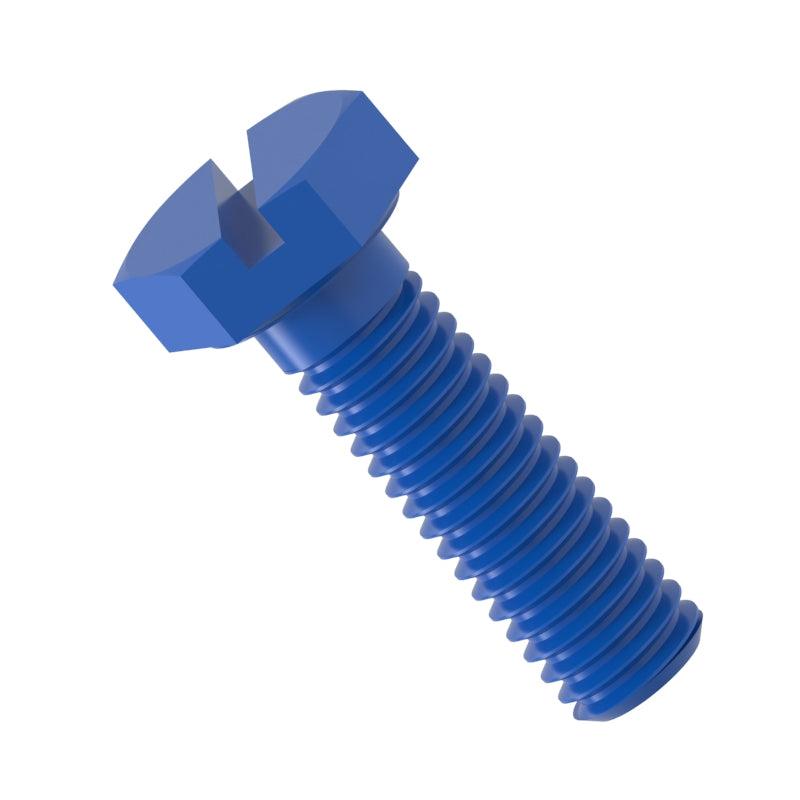

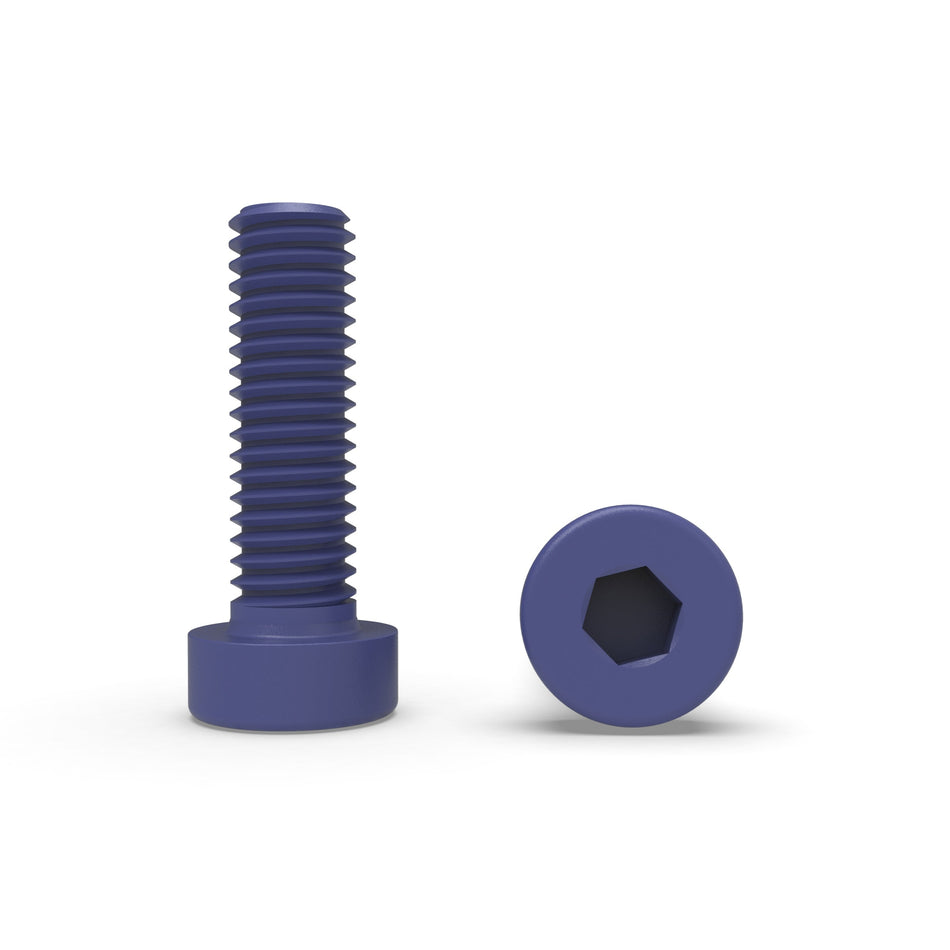

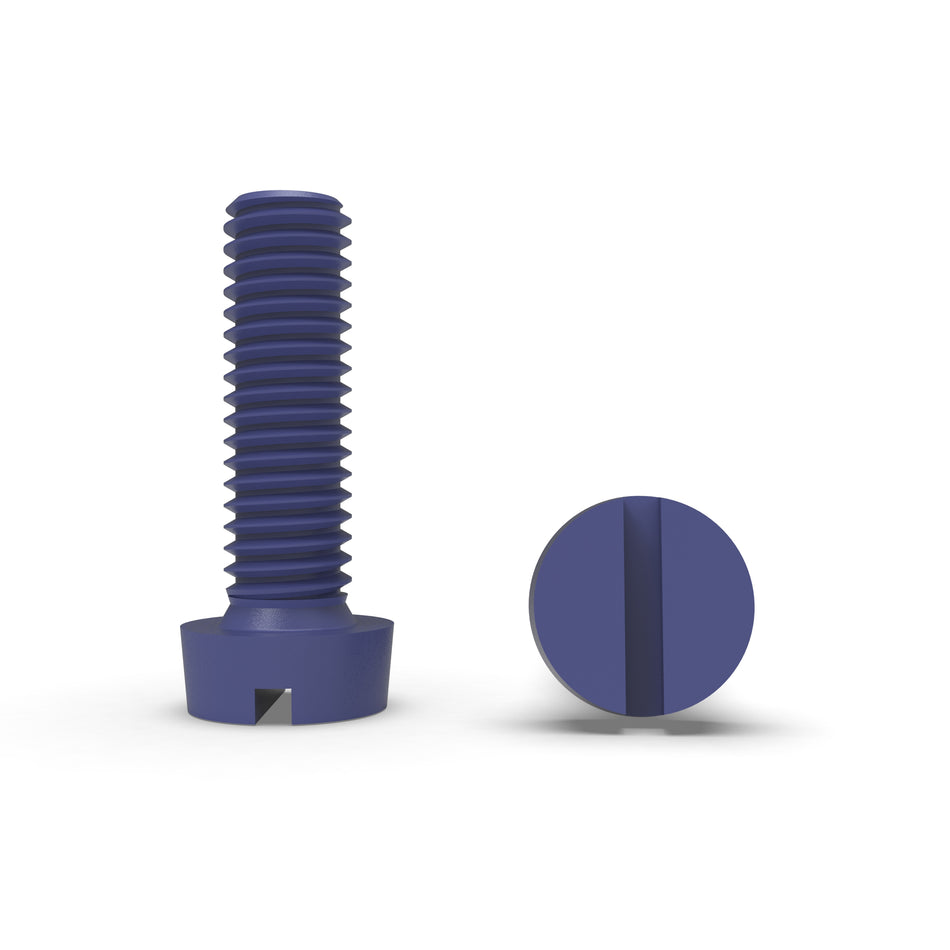

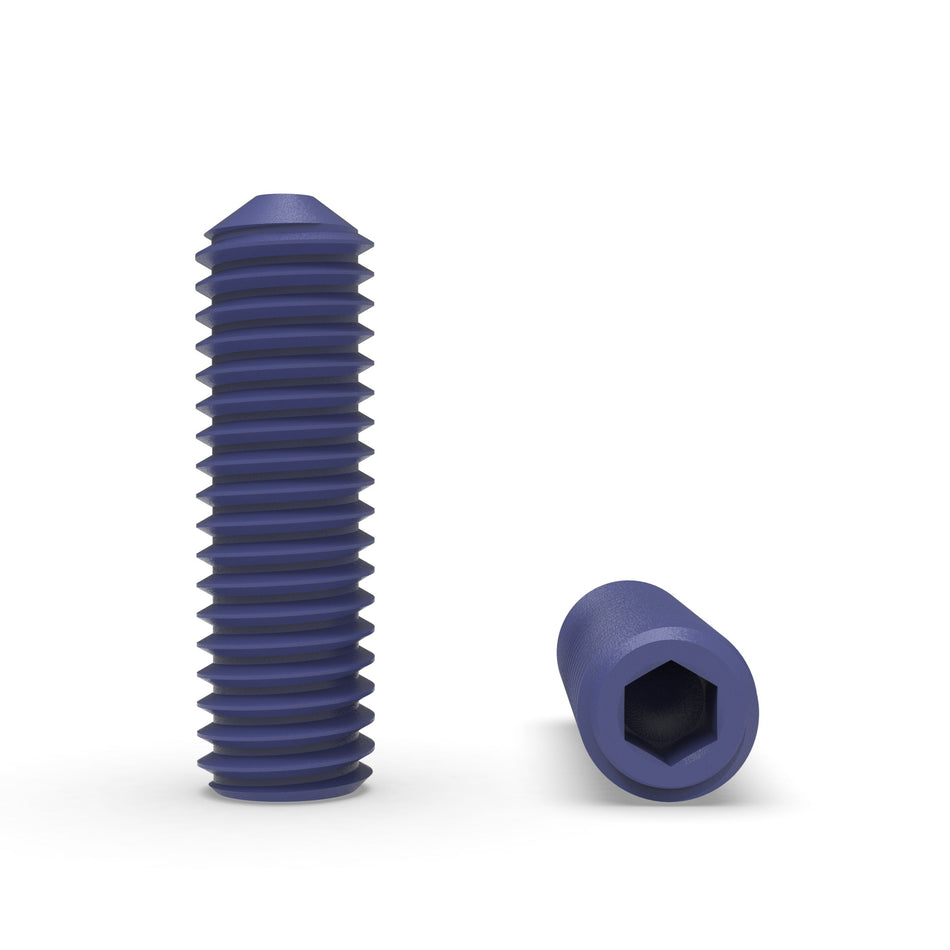

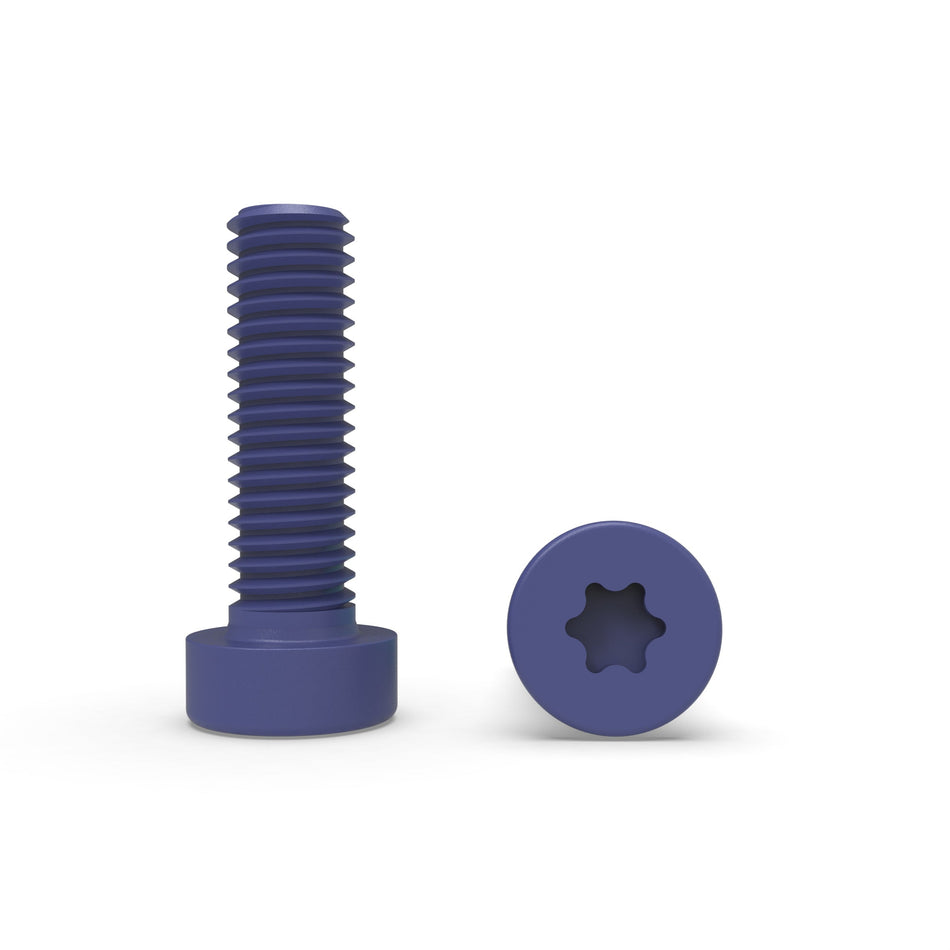

What are PTFE Coated A2-70 Stainless Steel Fasteners

PTFE Coated A2 Stainless Steel Fasteners, also known as 304 stainless steel, which is then coated with Polytetrafluoroethylene (PTFE). The A2 stainless steel provides excellent corrosion resistance, durability, and strength, making these fasteners suitable for various industrial applications. The PTFE coating, known for its low

friction and non-stick properties, enhances the fasteners' resistance to corrosion and chemicals, and provides a smooth, non-reactive surface. This coating also makes the fasteners easier to install and remove, as it reduces the torque required for tightening and loosening. PTFE Coated A2 Stainless Steel Fasteners are commonly used in environments where exposure to corrosive substances, extreme temperatures, or wet conditions is a concern, such as in the chemical, marine, and food processing industries. Fasteners, also known as 304 stainless steel, which is then coated with Polytetrafluoroethylene (PTFE). The A2 stainless steel provides excellent corrosion resistance, durability, and strength, making these fasteners suitable for various industrial applications. The PTFE coating, known for its low friction and non-stick properties, enhances the fasteners' resistance to corrosion and chemicals, and provides a smooth, non-reactive surface. This coating also makes the fasteners easier to install and remove, as it reduces the torque required for tightening and loosening. PTFE Coated A2 Stainless Steel Fasteners are commonly used in environments where exposure to corrosive substances, extreme temperatures, or wet conditions is a concern, such as in the chemical, marine, and food processing industries.