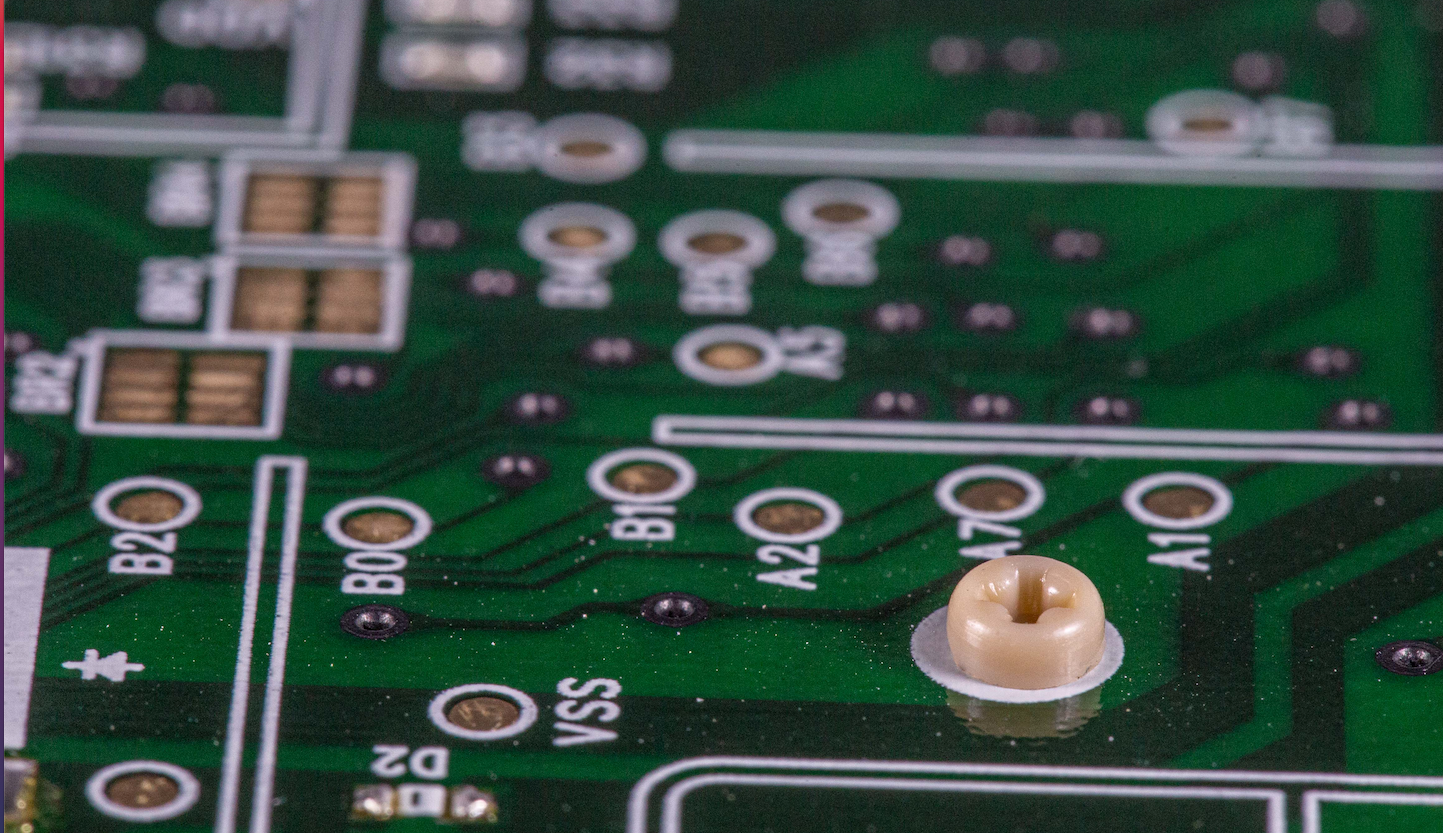

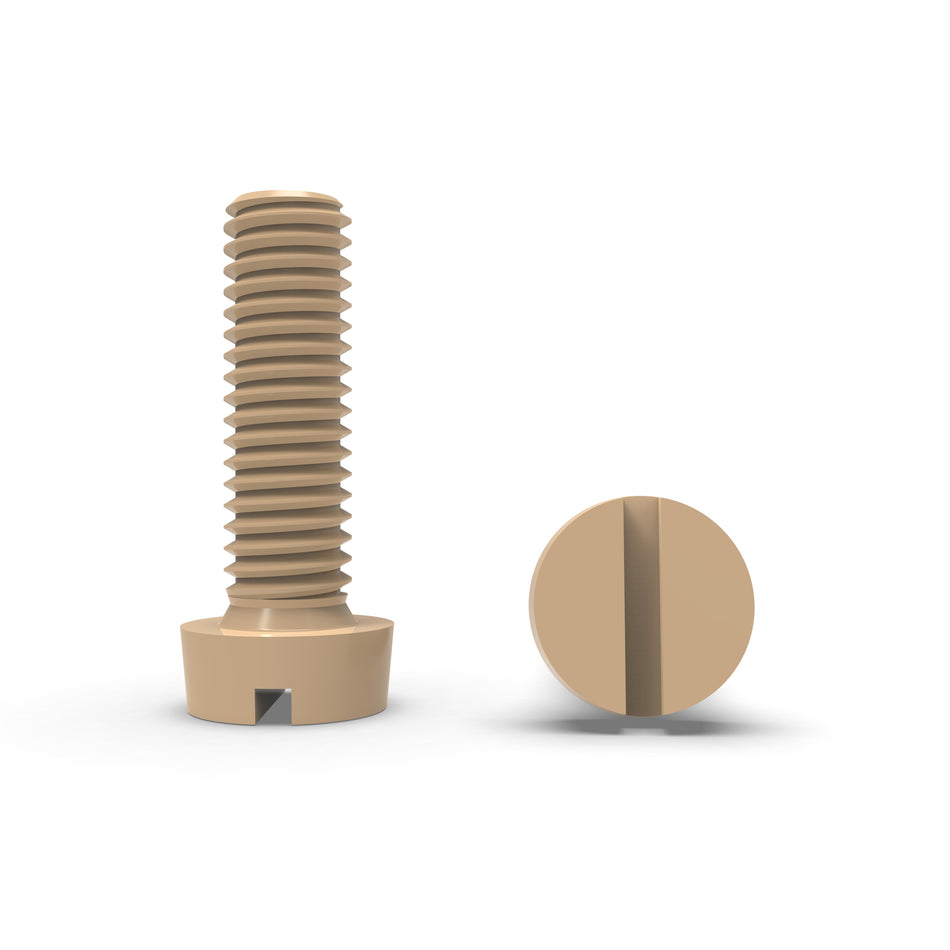

PEEK Screws

High Tensile Strength

When compared to other polymer screws such as Nylon and ABS PEEK outperforms in mechanical capability, even at very high temperatures.

High Temperature Resistance

180°C constant use and up to 250°C peak.

Outstanding properties

Suitable for challenging environments.