8 Products

Custom Sizes

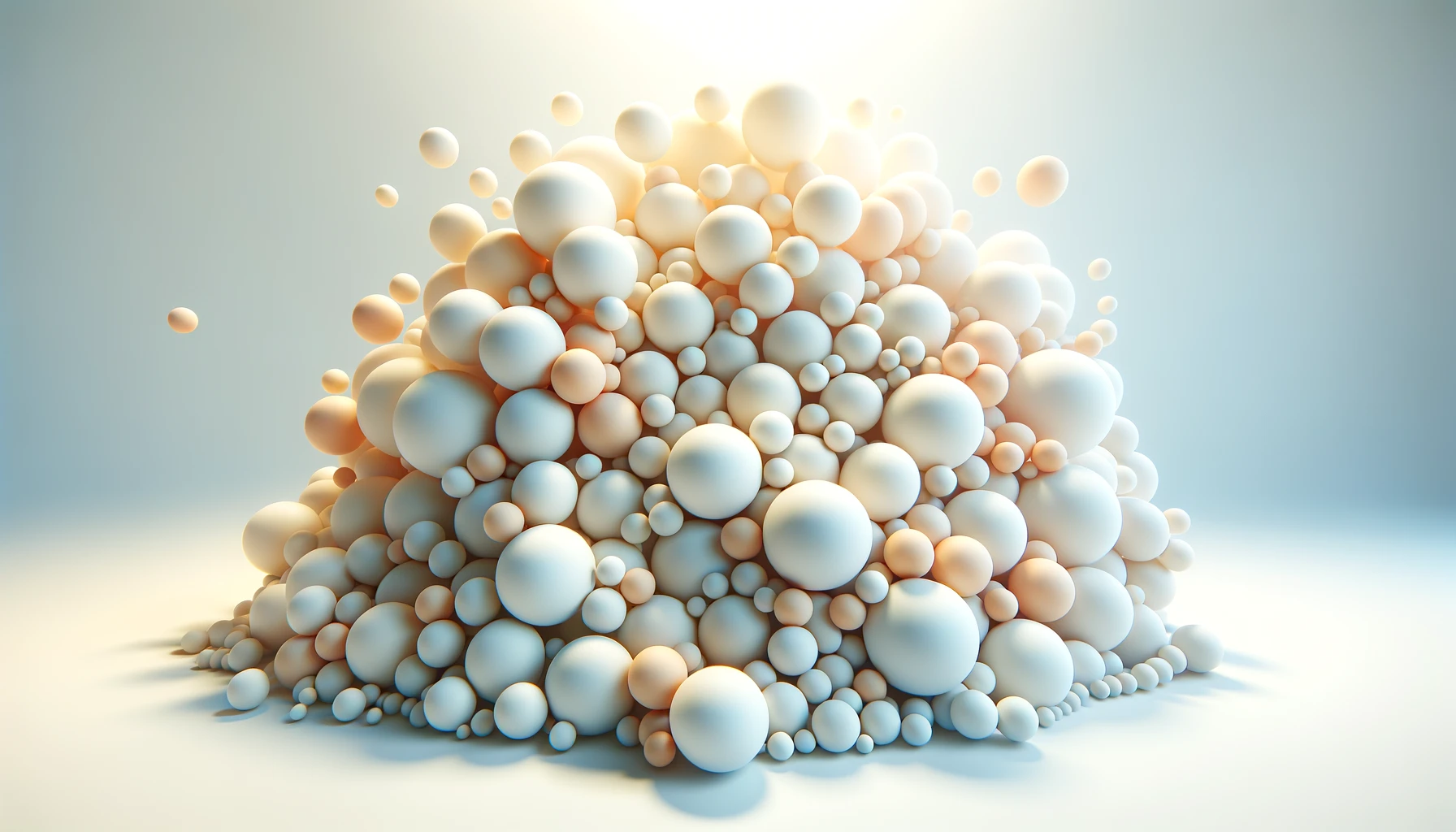

Polymer balls, engineered from high-grade synthetic materials, embody the convergence of advanced materials science and precision engineering. These spherical objects, crafted from various polymers such as polyethylene, polypropylene, PEEK, and polyvinyl chloride (PVC), are tailored to meet the diverse demands of modern industry and technology. Their applications range from mechanical engineering and fluid dynamics to biomedical devices and consumer products, showcasing their versatility and indispensability.

Applications:

- Mechanical Engineering: Utilized as bearings in lightweight applications, reducing friction and wear in machinery.

- Fluid Dynamics: Serve as valve components in hydraulic and pneumatic systems, optimizing flow control with their smooth surfaces and resilience.

- Biomedical: Employed in drug delivery systems and diagnostic tools, benefitting from their biocompatibility and controlled-release capabilities.

- Consumer Products: Integral to sports equipment, toys, and decorative items, valued for their safety and aesthetic qualities.

Features:

- Material Diversity: Available in a range of polymers, each offering unique properties such as chemical resistance, flexibility, and durability.

- Precision Engineering: Manufactured with high dimensional accuracy and surface finish, ensuring consistent performance in critical applications.

- Environmental Resistance: Exhibits superior resistance to corrosive substances, UV radiation, and extreme temperatures, maintaining integrity in harsh conditions.

- Customization: Can be tailored in terms of size, density, and color to suit specific requirements, enhancing their applicability across sectors.

Advantages:

- Durability: Polymer balls offer exceptional longevity, reducing the need for frequent replacements and maintenance.

- Cost-Effectiveness: They are more economical than their metal counterparts, providing cost savings without compromising quality.

- Lightweight: Their low density makes them ideal for applications where weight reduction is crucial, enhancing efficiency and performance.

- Eco-friendly Options: Many polymer balls are recyclable, supporting sustainability initiatives by minimizing waste.