5 Products

High Performance Polymer Plastic Rods and Bars: Manufacturing and Applications

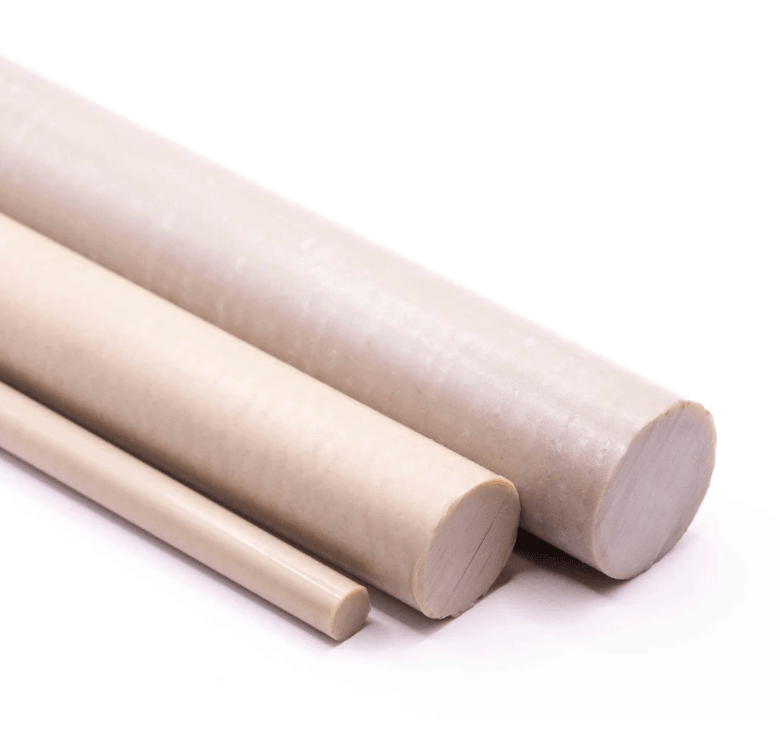

High-performance polymer plastic rods and bars are essential components in various industries, known for their exceptional properties and versatility. This article will delve into the manufacturing process of high-performance polymer plastic rods and bars, with a focus on notable materials like PEEK rods, PTFE bars, PVDF rods, and other polymer bars. Additionally, we will explore their diverse applications across different sectors.

Manufacturing Process:

The production of high-performance polymer plastic rods and bars involves advanced polymer processing techniques to ensure the desired material properties are achieved. The key steps in the manufacturing process include:

-

Polymer Selection: The choice of polymer is a critical first step and depends on the intended application. PEEK (Polyether Ether Ketone), PTFE (Polytetrafluoroethylene), PVDF (Polyvinylidene Fluoride), and other high-performance polymers are selected for their exceptional chemical resistance, thermal stability, and mechanical strength.

-

Polymer Extrusion or Moulding: Depending on the material and specifications, the polymer is either extruded or moulded into the desired rod or bar shape. Extrusion involves melting the polymer and forcing it through a die to create a continuous rod or bar, ensuring uniform dimensions and material properties. In contrast, molding involves shaping the polymer using a mould and then curing it to achieve the final form.

-

Cooling and Solidification: The extruded or moulded polymer is rapidly cooled to solidify the material and prevent deformation. Cooling methods may include air cooling, water quenching, or other specialised techniques.

-

Cutting and Finishing: Once solidified, the polymer rod or bar is cut to the desired length and may undergo additional finishing processes, such as polishing, machining, or surface coating, to enhance specific properties such as surface smoothness, wear resistance, or electrical conductivity.

Notable High-Performance Polymer Rods and Bars:

-

PEEK Rods: PEEK is a high-performance thermoplastic renowned for its exceptional mechanical strength, chemical resistance, and excellent thermal stability. PEEK rods are widely used in industries such as aerospace, medical, and oil and gas for manufacturing components like bushings, bearings, seals, and pump parts.

-

PTFE Bars: PTFE, commonly known as Teflon, is celebrated for its outstanding non-stick properties and low friction coefficient. PTFE bars are utilised in various applications, including the chemical industry for manufacturing gaskets, seals, and bearings, as well as in the electronics industry for electrical insulation.

-

PVDF Rods: PVDF boasts excellent chemical resistance, UV stability, and flame retardancy. PVDF rods are prevalent in the construction industry for architectural and cladding applications, as well as in chemical and semiconductor industries for their corrosion-resistant properties.

-

Other Polymer Bars: Beyond PEEK, PTFE, and PVDF, a range of other high-performance polymers offer unique combinations of properties suitable for specialised applications. For instance, PPS (Polyphenylene Sulfide) and POM (Polyoxymethylene) are commonly used in the automotive and electronics industries for their excellent mechanical and electrical properties.

Applications Across Industries:

-

Aerospace: High-performance polymer plastic rods and bars, such as PEEK, are crucial in aerospace for their lightweight nature, high strength-to-weight ratio, and resistance to aviation fluids and temperature variations. They are used in applications like bearings, bushings, and structural components.

-

Medical and Healthcare: PEEK rods are extensively used in medical devices and equipment, such as orthopaedic implants, dental instruments, and surgical components, owing to their biocompatibility, strength, and resistance to sterilisation processes.

-

Chemical Processing: PTFE bars play a pivotal role in the chemical industry, where their chemical resistance and low friction properties make them ideal for manufacturing gaskets, seals, and bearings that can withstand harsh chemical environments.

-

Electronics: High-performance polymer bars like PPS and POM are utilised in the electronics industry for manufacturing insulators, connectors, and components with superior electrical insulation properties and resistance to heat and chemicals.

-

Construction: PVDF rods find extensive use in architectural applications, including roofing systems, cladding, and facades, due to their weather resistance and durability.

-

Automotive: High-performance polymer bars are used in the automotive sector for manufacturing engine components, bushings, and bearings, contributing to enhanced fuel efficiency and durability.

High-performance polymer plastic rods and bars, including PEEK rods, PTFE bars, PVDF rods, and other polymer bars, are critical materials that have revolutionised various industries. Their manufacturing process involves careful selection of polymers and precise extrusion or moulding techniques, resulting in materials with exceptional properties. These versatile materials cater to a wide array of applications, from aerospace and medical to electronics and construction, making them indispensable in modern manufacturing and technology.