14 Products

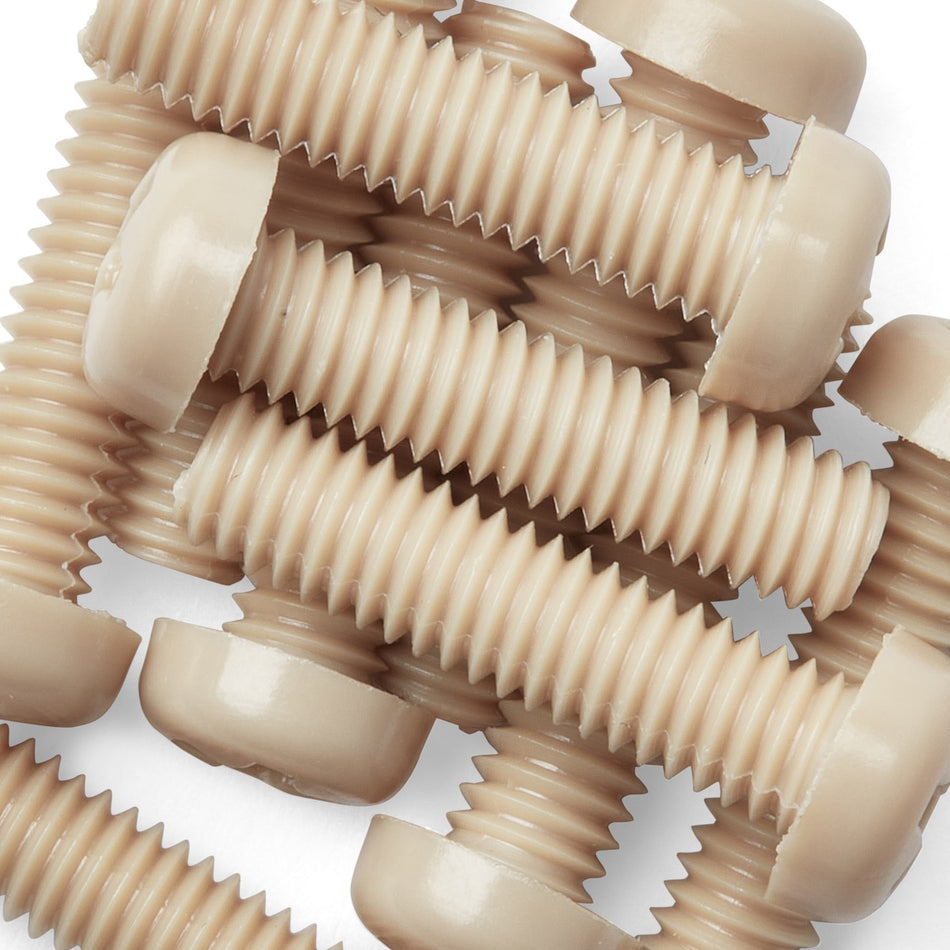

Polymer Pan Head Screws such as those made of PEEK, RENY, PEEK GF30, PPS, PC, & PVDF for HighPerformancePolymer.co.uk in their Precision Screws Range can be used for a variety of different specialised engineering purposes.

High Performance Polymer Pan Head Screws are fasteners made from advanced polymers such as PEEK, PVDF, RENY, and Polycarbonate. These screws offer excellent mechanical, thermal, and chemical properties compared to traditional metal screws.

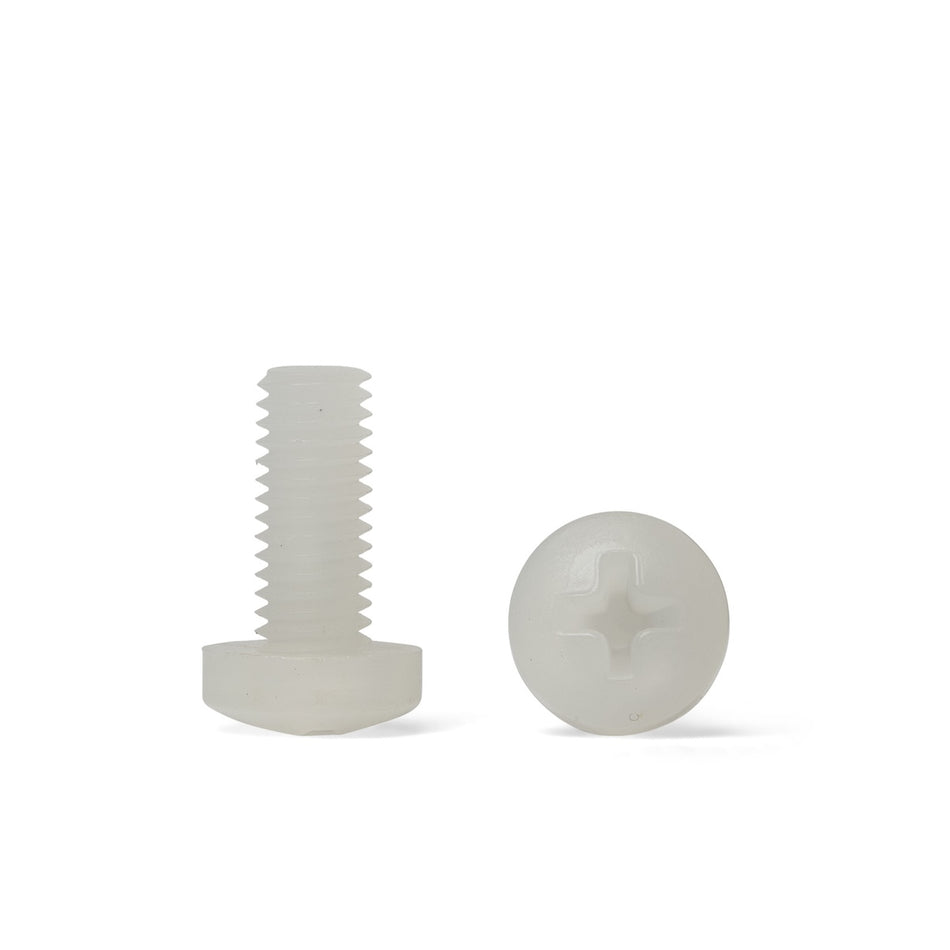

One of the key benefits of High Performance Polymer Pan Head Screws is their resistance to wear and corrosion. They are able to withstand exposure to harsh environments, including chemicals, high temperatures, and high stress. This makes them ideal for use in a wide range of applications, including medical, aerospace, and automotive.

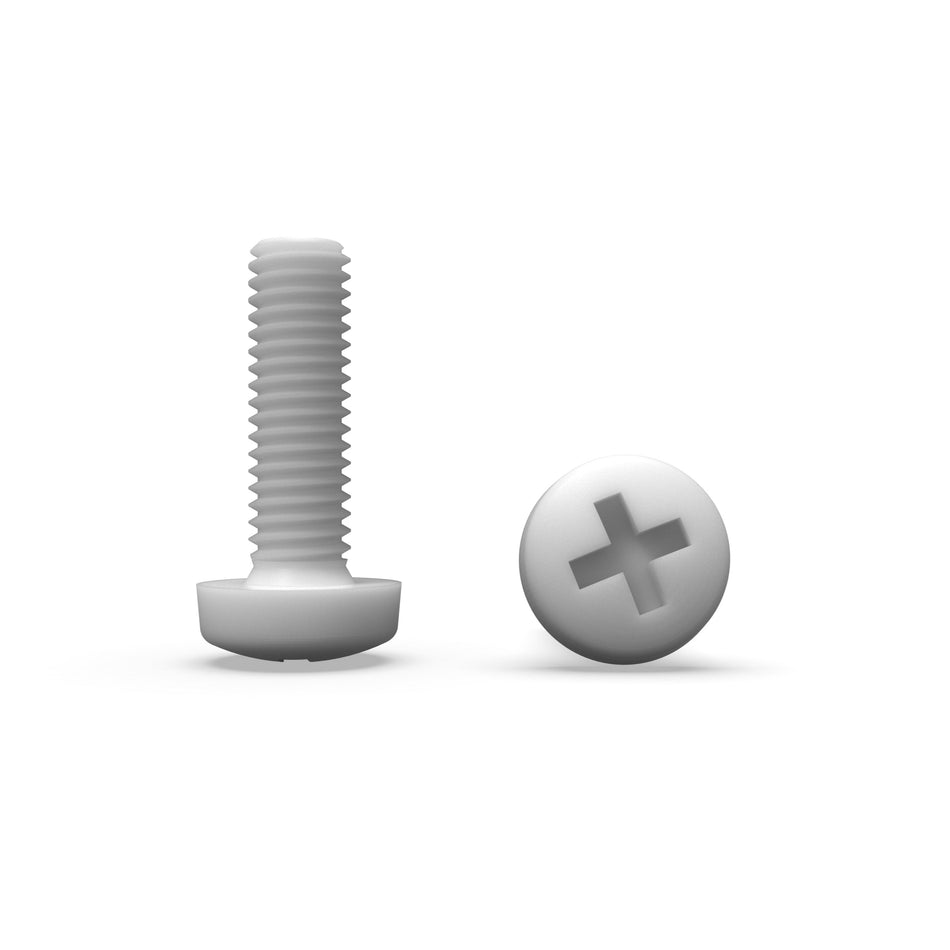

High Performance Polymer Pan Head Screws are designed with a flat, circular head and a slightly tapered body. The design allows for easy installation and removal using a variety of tools, including screwdrivers and hex keys. The pan head design also provides a larger bearing surface than other types of screw heads, reducing the risk of damage to the surface being fastened.

The design of High Performance Polymer Pan Head Screws is critical to ensure that they meet the specific requirements of the application. The design process involves careful consideration of factors such as the operating environment, the load requirements, and the desired mechanical properties of the component. CAD software is often used to create detailed 3D models of the screw to ensure that it meets the exact requirements of the customer.

Manufacturing of High Performance Polymer Pan Head Screws involves advanced production techniques such as injection molding, CNC machining, or extrusion. These techniques allow for the production of complex shapes and precise dimensions, ensuring that the final product meets the customer's exact specifications.

Overall, High Performance Polymer Pan Head Screws offer a range of benefits over traditional metal screws, including resistance to wear and corrosion, easy installation and removal, and a larger bearing surface. These screws are increasingly popular in a wide range of industries due to their ability to provide exceptional performance in harsh environments.