14 Products

Understanding Ultem PEI (Polyetherimide) and Its Versatile Applications in Fasteners

In the world of advanced engineering polymers, Ultem PEI (Polyetherimide) stands out as a remarkable material known for its exceptional properties and diverse range of applications. In this comprehensive guide, we will delve into the world of Ultem PEI, exploring its chemical characteristics compared to other polymers and its specific uses in the manufacturing of screws, nuts, bolts, and washers. Whether you are an engineer, a manufacturer, or simply curious about this extraordinary material, read on to discover the fascinating world of Ultem PEI.

What is Ultem PEI?

Ultem PEI, short for Polyetherimide, is a high-performance thermoplastic that belongs to the polyimide family of polymers. Developed and manufactured by SABIC (Saudi Basic Industries Corporation), Ultem is renowned for its outstanding combination of mechanical, thermal, and electrical properties. Its unique chemical structure, consisting of alternating imide and ether groups, contributes to its remarkable characteristics.

Chemical Characteristics of PEI Compared to Other Polymers

To truly appreciate the exceptional properties of Ultem PEI, it is essential to compare it to other commonly used polymers. Here, we highlight some key chemical characteristics that set PEI apart:

1. High Temperature Resistance

Ultem PEI exhibits exceptional thermal stability, with a glass transition temperature (Tg) of approximately 217°C (423°F). This high Tg value allows Ultem to maintain its mechanical properties at elevated temperatures, making it an ideal choice for applications that require exposure to heat and harsh environments. In contrast, many other polymers may soften or deform under similar conditions.

2. Outstanding Chemical Resistance

PEI offers excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This chemical inertness makes it suitable for applications where exposure to corrosive substances is a concern. Unlike some polymers that may degrade or react with chemicals, Ultem PEI remains stable and maintains its integrity.

3. Dimensional Stability

Ultem PEI boasts remarkable dimensional stability, meaning it maintains its shape and size even when subjected to varying temperature and humidity conditions. This property is crucial for precision components like screws, nuts, bolts, and washers, as it ensures that these parts will perform reliably over time.

4. Electrical Insulation

PEI is an excellent electrical insulator, making it suitable for applications in the electronics and electrical industries. Its high dielectric strength and low moisture absorption help maintain electrical performance, even in humid environments.

5. High Strength-to-Weight Ratio

One of Ultem PEI's standout characteristics is its impressive strength-to-weight ratio. It offers exceptional mechanical strength while remaining relatively lightweight. This makes it an ideal choice for applications where both strength and weight considerations are critical.

6. Low Smoke and Toxic Gas Emission

In safety-critical applications, such as aerospace and transportation, Ultem PEI's low smoke and toxic gas emission properties are highly valued. In the event of a fire, PEI minimizes the release of harmful gases, contributing to improved safety.

Uses of PEI in Fasteners: Screws, Nuts, Bolts, and Washers

Ultem PEI's exceptional properties make it a preferred material for the production of screws, nuts, bolts, and washers across various industries. Let's explore its specific applications in these essential fastener components:

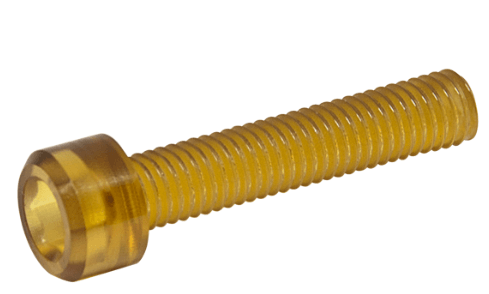

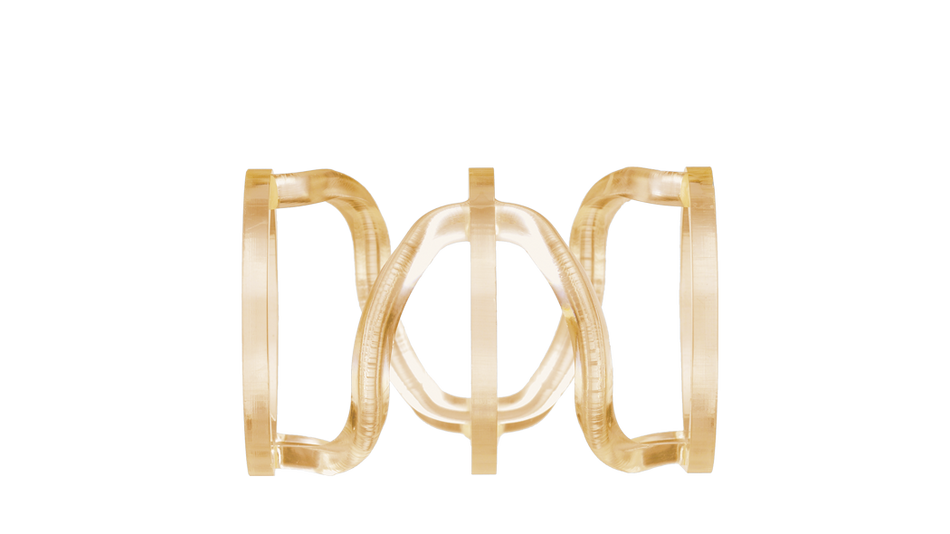

1. ULTEM PEI Screws

Ultem PEI screws find their place in industries requiring high-temperature resistance and exceptional mechanical strength. These screws are used in applications such as automotive manufacturing, aerospace, and electronics, where they securely fasten components even in extreme conditions. The high temperature resistance of PEI ensures that the screws maintain their structural integrity, while their electrical insulating properties make them ideal for electronic assemblies.

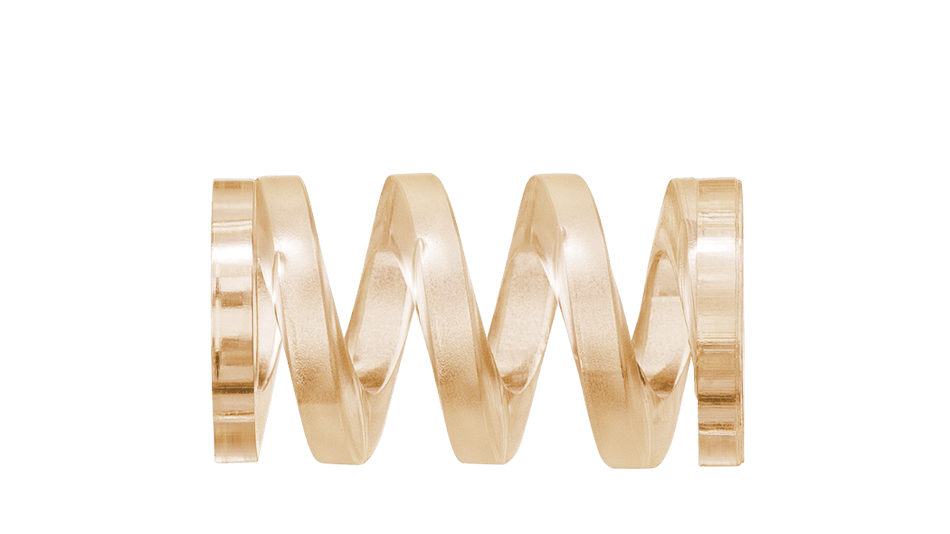

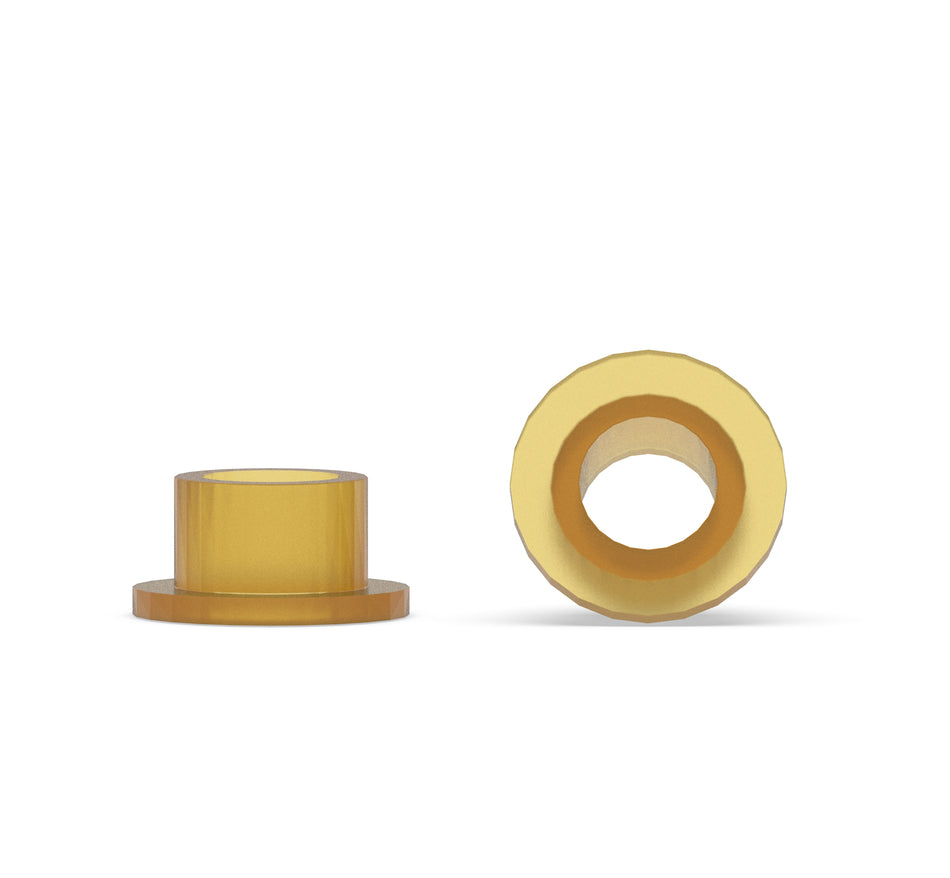

2. ULTEM PEI Nuts

PEI nuts are known for their reliability and durability. They are widely used in applications that demand resistance to chemicals, high temperatures, and dimensional stability. The chemical resistance of Ultem PEI nuts ensures that they can withstand exposure to various substances, making them suitable for use in chemical processing plants and laboratories.

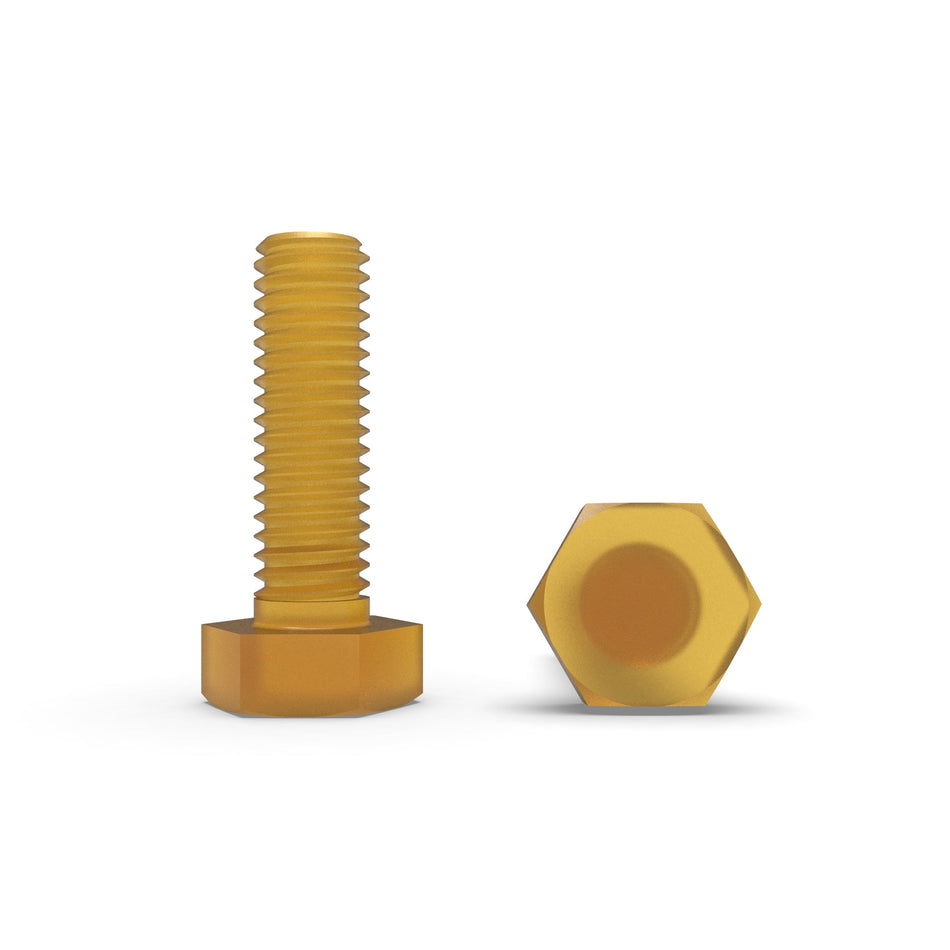

3. ULTEM Bolts

Ultem PEI bolts are favored for their ability to maintain their strength and integrity at elevated temperatures. They are commonly used in industries such as automotive, where engines and exhaust systems generate significant heat. PEI bolts can endure these harsh conditions without compromising performance, ensuring the safety and reliability of critical components.

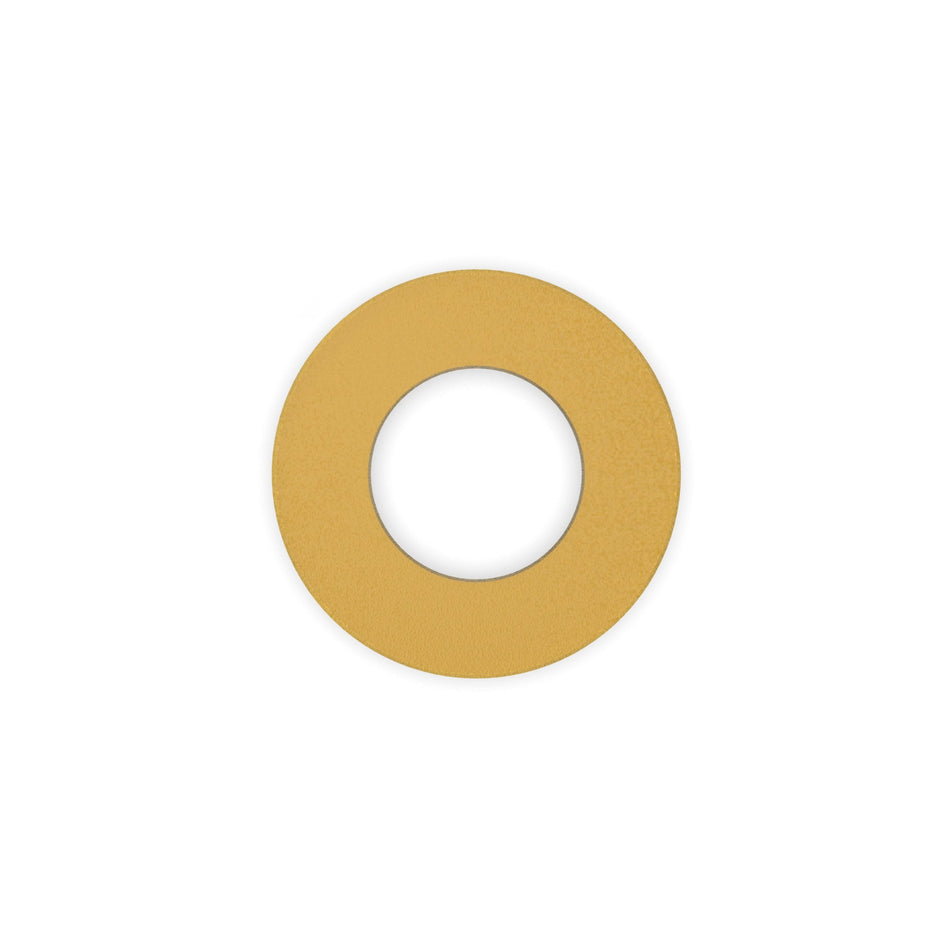

4. ULTEM Washers

PEI washers play a vital role in ensuring a secure and lasting connection between fasteners and the components they hold together. These washers are prized for their dimensional stability, which prevents warping or deformation under load. They are used in a wide range of applications, including machinery, construction, and electronics assembly.

Ultem PEI (Polyetherimide) is a remarkable engineering polymer known for its exceptional chemical characteristics and versatility. Its high-temperature resistance, outstanding chemical resistance, dimensional stability, electrical insulation properties, and low smoke and toxic gas emission make it a top choice for fasteners like screws, nuts, bolts, and washers. Whether you require reliable fasteners for extreme conditions in aerospace, automotive, or other industries, Ultem PEI is a material that delivers performance, durability, and peace of mind. Invest in the future of fasteners with Ultem PEI and experience the benefits of this exceptional polymer firsthand.

Ultem PEI (Polyetherimide) is available in several grades, each formulated to meet specific performance requirements and applications. These grades offer variations in properties such as temperature resistance, flame resistance, and chemical resistance. Here are some of the common grades of Ultem PEI:

-

Ultem 1000:

- General-Purpose Grade: Ultem 1000 is the most widely used grade and is known for its excellent combination of mechanical strength, dimensional stability, and electrical properties. It has a high glass transition temperature (Tg) of approximately 217°C (423°F) and is suitable for a wide range of applications, including aerospace, automotive, and electronics.

-

Ultem 1010:

- FDA-Compliant Grade: Ultem 1010 is specifically designed to meet FDA requirements for food contact materials. It offers the same high-temperature resistance and mechanical properties as Ultem 1000 but with the added advantage of being suitable for use in food processing and medical applications where compliance with regulatory standards is essential.

-

Ultem 2300:

- Glass-Filled Grade: Ultem 2300 incorporates glass fiber reinforcement, which enhances its stiffness and dimensional stability while retaining high-temperature resistance. This grade is ideal for applications that require increased strength and rigidity, such as structural components and electrical insulators.

-

Ultem 2200:

- Unfilled Grade: Ultem 2200 is an unfilled, general-purpose grade similar to Ultem 1000 but with slightly modified properties. It offers excellent electrical insulating properties and is often used in electrical and electronic applications, including connectors, sockets, and insulating components.

-

Ultem 4100:

- Flame-Retardant Grade: Ultem 4100 is formulated with flame-retardant additives to meet stringent fire safety regulations. It exhibits excellent flame resistance while maintaining many of the characteristics of Ultem 1000, making it suitable for applications where fire safety is a concern, such as aerospace interiors and electrical enclosures.

-

Ultem 5000:

- Enhanced Chemical Resistance Grade: Ultem 5000 series includes grades with improved chemical resistance. These versions are designed to withstand exposure to a broader range of chemicals and solvents, making them suitable for chemical processing equipment, laboratory instruments, and applications where resistance to aggressive environments is required.

-

Ultem 6450:

- Transparent Grade: Ultem 6450 is a transparent variant of Ultem PEI. It offers excellent clarity, high-temperature resistance, and good mechanical properties. It is often used in applications where transparency and heat resistance are both essential, such as sight glasses, lighting components, and medical devices.

-

Ultem HU1004:

- High-Flow Grade: Ultem HU1004 is designed for injection molding applications where high flow and ease of processing are critical. This grade allows for intricate and thin-walled part designs while still offering the inherent benefits of Ultem, including high-temperature resistance and mechanical strength.

These are just a few examples of the various Ultem PEI grades available. The choice of grade depends on the specific requirements of your application, such as temperature resistance, chemical compatibility, flame resistance, and mechanical properties. Selecting the right Ultem grade ensures that your product or component meets the necessary performance criteria and regulatory standards. When considering Ultem PEI for your project, consult with a materials engineer or supplier to determine the most suitable grade for your application's needs.