115 Products

Motorsport uses of Polymer Screws, Nuts, Bolts, and Fasteners

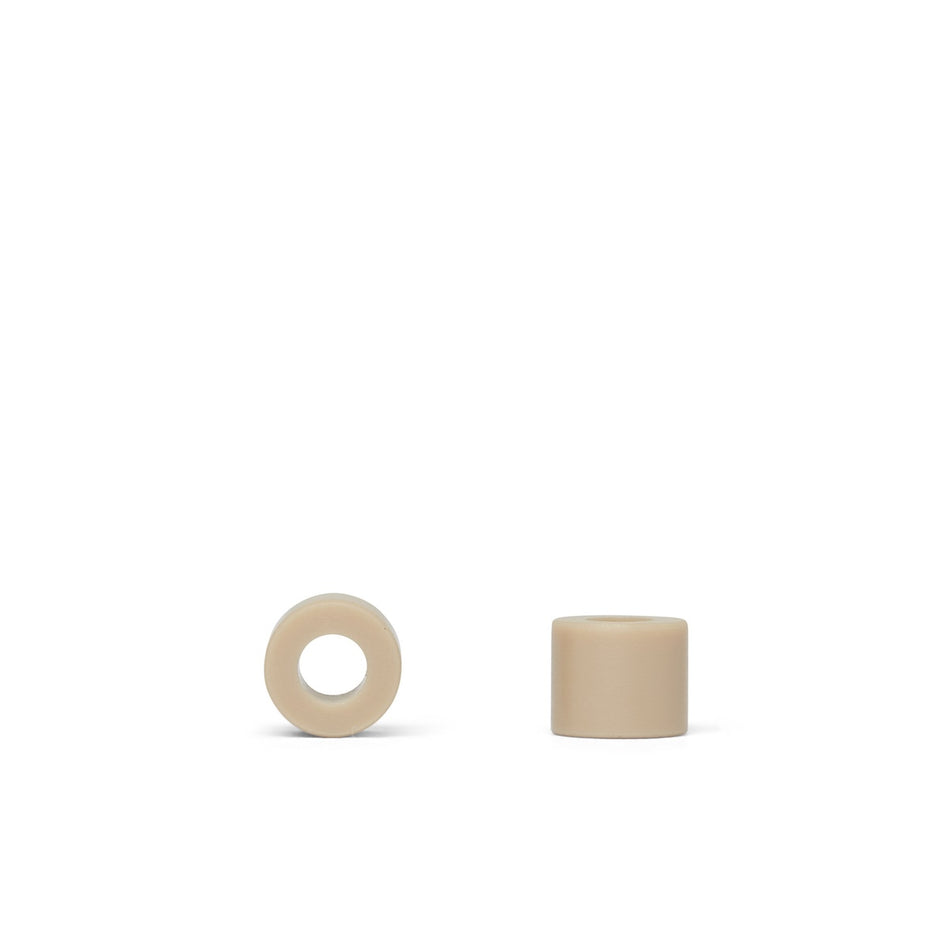

Polymer screws, nuts, bolts, and fasteners are commonly used in the Formula 1 industry to secure and fasten various parts and components of a racing car together. These types of fasteners are made from a variety of polymers, such as plastic, rubber, or composite materials, and are designed to be strong, durable, and resistant to corrosion.

One of the main advantages of using polymer fasteners in Formula 1 is that they are typically lighter in weight than metal fasteners, which can help to reduce the overall weight of the racing car and improve its performance. Additionally, polymer fasteners are often more resistant to corrosion and wear than metal fasteners, which can help to extend the life of the car and reduce maintenance costs.

Some common examples of polymer screws, nuts, bolts, and fasteners that might be used in Formula 1 include:

-

Plastic screws and bolts: These types of fasteners are often used to secure plastic components, such as dashboard and trim pieces, to the racing car. They may be made from a variety of polymers, such as polypropylene or polycarbonate, and are typically resistant to corrosion and wear.

-

Rubber nuts and bolts: These types of fasteners are often used to secure components that are subjected to vibration or movement, such as suspension components or engine mounts. They may be made from a variety of rubber compounds, such as neoprene or natural rubber, and are typically resistant to wear and fatigue.

-

Composite fasteners: These types of fasteners are made from a combination of polymers and other materials, such as fiberglass or carbon fiber. They are often used in high-stress applications, such as in the engine or transmission, due to their high strength and durability.

Overall, the use of polymer screws, nuts, bolts, and fasteners can help to improve the performance, efficiency, and durability of Formula 1 racing cars, and are an important part of the design and manufacturing process.

Formula 1, also known as F1, is a type of open-wheel racing that is sanctioned by the Fédération Internationale de l'Automobile (FIA). It is considered to be the highest class of single-seater auto racing in the world, and is known for its high-speed and high-tech racing cars.

In Formula 1, teams of engineers and technicians design and build specialized racing cars, which are then driven by professional drivers in a series of races called Grand Prix. The Grand Prix are held on a variety of tracks around the world, including circuits in Europe, Asia, North America, and South America.

The Formula 1 industry is highly competitive, and teams are always looking for ways to gain an advantage over their rivals. This often involves using advanced technologies and innovative engineering solutions to improve the performance of their cars.

In addition to the racing itself, Formula 1 also includes a significant business and commercial aspect. Teams rely on sponsorship deals and other forms of funding to support their operations, and the sport generates billions of dollars in revenue each year through television rights, ticket sales, and other sources.

Overall, Formula 1 is a highly sophisticated and technologically advanced industry that combines the thrill of high-speed racing with the challenges of cutting-edge engineering and business management.