Dimension Table

Dimensions for HPLC PEEK Plug (M6) in all available sizes are shown according to the product drawing above.

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

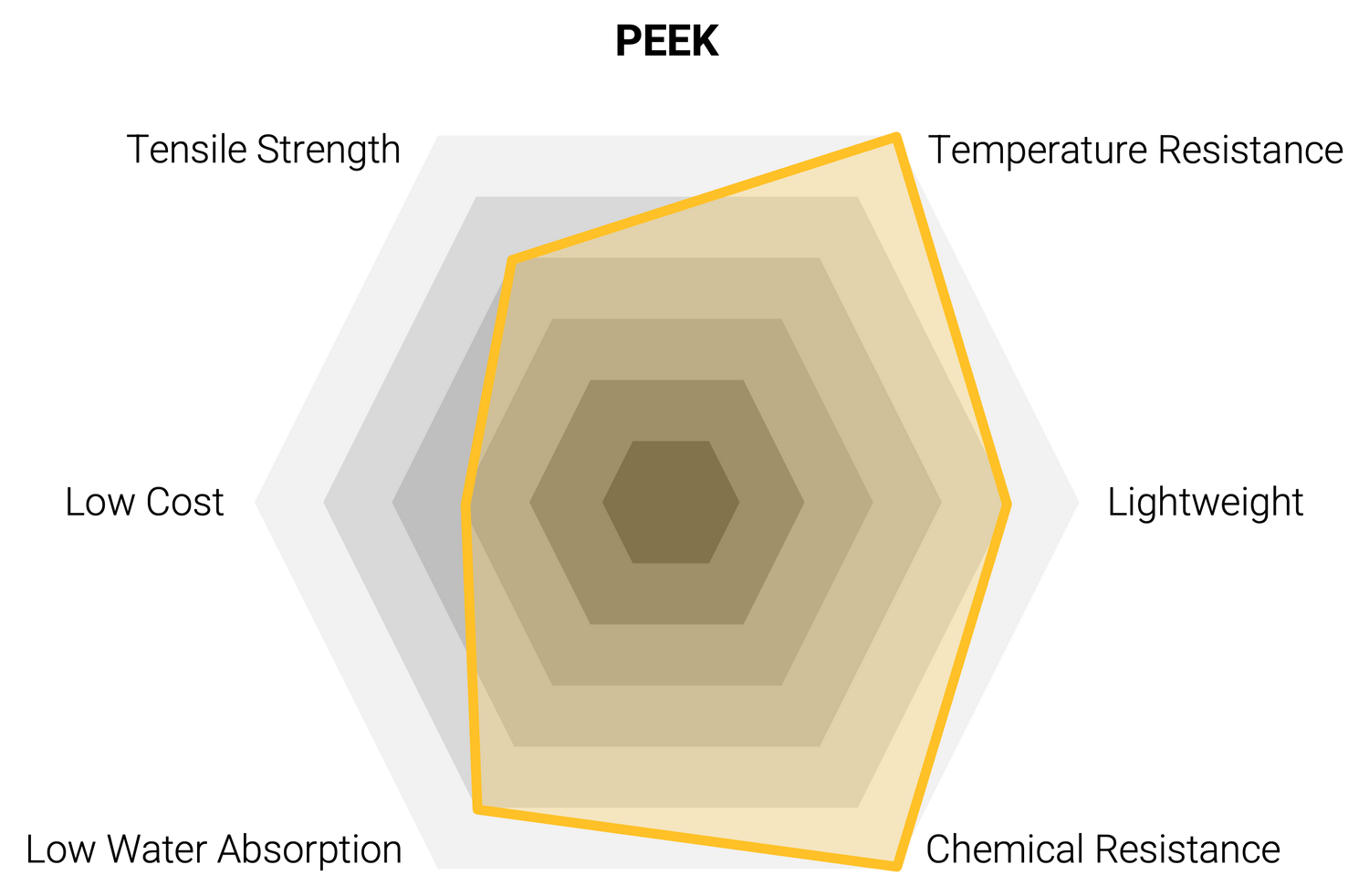

Material: PEEK

Measurement System: Metric

Colour: Natural/Beige

Maximum Temperature: 260°C/500°F

Flammability: UL94 V-0

HPLC PEEK Plug (M6) conform to the following Standards/Norms:

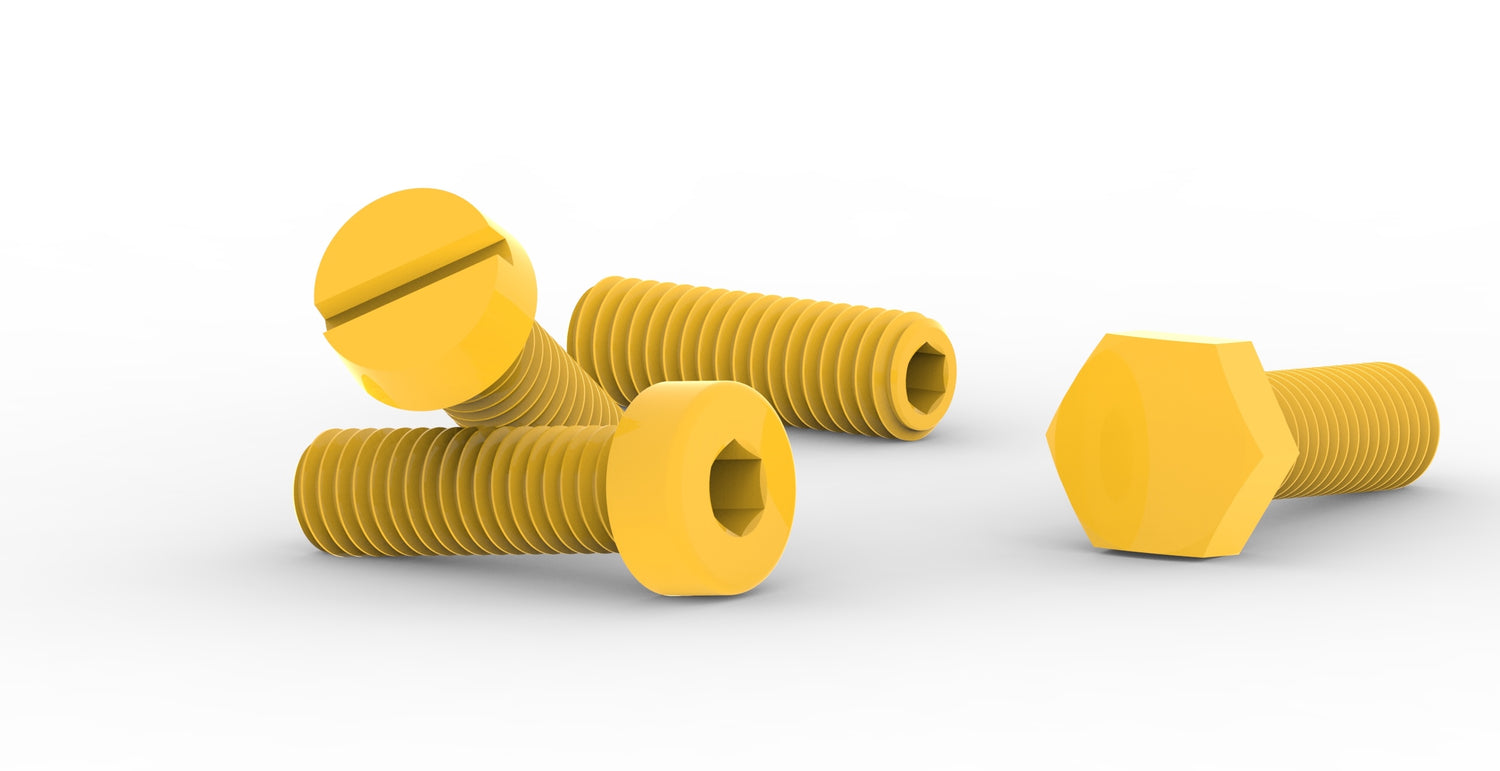

High-Performance Liquid Chromatography (HPLC) Plug manufactured from PEEK. These specialised end plugs are designed to securely seal the ends of HPLC columns, ensuring leak-free connections and maintaining optimal system performance:

Thread size: M6

Thread length: 10.00mm

Material: PEEK

Features: Flat Bottom, Finger Tightening

Finger Tightening:

The finger-tightening option allows this fitting to be manually tightened without the need for wrenches or other tools. This design features a knurled surface, which provides a better grip and allows the user to easily tighten the fitting by hand. These fittings are particularly advantageous in applications requiring frequent connection and disconnection, such as routine maintenance or changing columns.

Flat Bottom

A flat bottom HPLC fitting ensures secure, leak-free connections, essential for maintaining system integrity and accurate results. Its design minimises dead volume, reducing peak broadening and improving separation efficiency. Easy to install and compatible with various tubing, it enhances the reliability and performance of high-precision chromatographic analyses.

Manufactured in PEEK:

Chemical Resistance

Wide Range of Compatibility: PEEK exhibits excellent resistance to a broad spectrum of chemicals, including organic solvents, acids, and bases commonly used in HPLC. This ensures that the fittings do not degrade or react with the mobile phases or samples.

Non-Contaminating: Because PEEK is chemically inert, it does not leach contaminants into the mobile phase, which is crucial for maintaining the purity and integrity of the samples.

Mechanical Strength and Durability

High Pressure Resistance: HPLC systems often operate at high pressures. PEEK has the mechanical strength to withstand these pressures without deforming or failing.

Wear Resistance: PEEK fittings are durable and can endure the repeated connect and disconnect cycles typical in HPLC applications, ensuring a long service life.

Thermal Stability

Wide Temperature Range: PEEK retains its mechanical properties over a wide temperature range. This makes it suitable for HPLC systems that may experience varying temperatures during operation.

Consistency: The thermal stability of PEEK ensures that the fittings maintain a consistent seal and mechanical performance even under fluctuating temperature conditions.

Biocompatibility

Non-reactive: PEEK is biocompatible and does not interact with biological samples. This makes it an ideal material for HPLC applications in pharmaceuticals, biotechnology, and clinical research where sample integrity is critical.

Safe for Sensitive Applications: PEEK's non-toxic nature makes it safe for use in applications involving sensitive or hazardous substances.

HPLC PEEK Plug direct applications:

Column Storage and Preservation:

Protecting Columns When Not in Use: PEEK end plugs are used to seal HPLC columns when they are not in use, preventing contamination and maintaining the integrity of the column's packing material.

Transporting Columns: When HPLC columns need to be transported between locations, end plugs ensure that the columns are securely sealed, preventing any potential damage or contamination.

Preventing Contamination:

Unused Ports: In complex HPLC systems with multiple ports and pathways, PEEK end plugs are used to seal unused ports to prevent contamination and maintain system cleanliness.

Sample Integrity: By sealing off open ends, these plugs help preserve the integrity of samples and solvents within the system, which is crucial for accurate and reliable results.

Maintenance and Downtime:

System Maintenance: During maintenance or cleaning of the HPLC system, PEEK end plugs are used to seal components that are not being serviced, ensuring that the rest of the system remains uncontaminated.

Extended Downtime: If an HPLC system is not going to be used for an extended period, end plugs can be employed to protect the system from dust, moisture, and other contaminants.

Method Development and Testing:

Isolation of Components: In method development or troubleshooting, PEEK end plugs can be used to isolate specific components of the HPLC system for testing and optimisation.

Calibration and Validation: During calibration and validation procedures, certain parts of the system may need to be temporarily sealed off to ensure accurate and precise measurements.

The PEEK data sheet is available as a PDF to download below.

Return components within 90 days for a full refund. Please see returns terms and conditions for further information.

| HPLC PEEK Plug (M6) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | Head Diameter (mm) | Head Height (mm) | Thread Length | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M6 | 9.00 | 8.00 | 10.00 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dimensions for HPLC PEEK Plug (M6) in all available sizes are shown according to the product drawing above.

Follow the link below to view our PEEK data sheet. This includes properties such as mechanical, electrical, thermal and chemical resistance.

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

50,000+ Fasteners In stock

No long lead times. We have a large range of PEEK fasteners available for express delivery (Dispatched the same day if ordered before 3PM Monday-Thursday).

Fasteners not available for express delivery will display the expected delivery date above the 'add to cart' button.

Manufacturer Direct Distributor

We are a manufacturer direct distributor, this allows us to ensure highly competitive prices and keep our shelves stocked. All of our products are manufactured to the highest standards and exhibit exceptional characteristics.

ISO9001 Certified

Certified through Quality Veritas. High Performance Polymer conforms to the ISO9001 quality management system. Certificates available on request.

Material Certificates

We provide full material traceability and can provide certification confirming material data and batch number, which can be traced back to the manufacturer.

Certificate Of Conformity

We also provide a certificate of conformity on request, confirming the product manufacturing standard and material.