PTFE Bushings

PTFE Bushings

Volume Discounts Available:

Show more Show less

Want it by XYZ?

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Instant Quote:

Submit a request for quote online by clicking the button below and a PDF quotation will be delivered to your inbox within 5 mins.

Material: PTFE

Measurement System: Metric

Colour: White/Natural

Continuous use temperature: 260°C

Flammability: UL94 V-0

PTFE Bushings conform to the following Standards/Norms:

Polytetrafluoroethylene (PTFE) bushings are crucial components in a variety of industries, valued for their exceptional properties and versatility. PTFE is a high-performance fluoropolymer known for its remarkable combination of low friction, chemical resistance, and thermal stability. PTFE bushings are designed to provide a reliable and low-friction interface between moving parts in mechanical systems, making them invaluable in numerous applications across diverse industries.

Properties and Characteristics

PTFE, often referred to by the brand name Teflon, possesses several key properties that make it an excellent choice for bushing applications:

-

Low Friction: PTFE has an exceptionally low coefficient of friction, even in dry conditions. This property reduces wear and energy consumption, contributing to the efficiency and longevity of mechanical systems.

-

Chemical Resistance: PTFE is highly resistant to a wide range of chemicals, acids, and solvents, making it suitable for applications where exposure to corrosive substances is a concern.

-

Thermal Stability: PTFE can withstand a wide temperature range, from extremely low temperatures to high temperatures without significant loss of its mechanical properties. This property makes PTFE bushings suitable for both cryogenic and high-temperature applications.

-

Low Moisture Absorption: PTFE has low moisture absorption, ensuring dimensional stability even in humid environments.

-

Electrical Insulation: PTFE is an excellent electrical insulator, making it suitable for use in electrical and electronic applications where electrical isolation is required.

-

Self-Lubrication: PTFE bushings can be impregnated with lubricating fillers or additives to provide self-lubricating properties, reducing the need for external lubrication.

Applications and Industries

PTFE bushings find extensive applications across various industries due to their exceptional properties. Some of the key industries that use PTFE bushings include:

1. Automotive Industry: PTFE bushings are widely employed in the automotive sector for applications such as suspension systems, steering components, and throttle linkages. Their low friction properties contribute to smooth and quiet vehicle operation while reducing wear.

2. Aerospace and Aviation: In the aerospace industry, where precision and reliability are paramount, PTFE bushings are used in aircraft landing gear assemblies, control systems, and cabin equipment. Their ability to maintain low friction in extreme conditions and resistance to high temperatures make them crucial in aviation.

3. Chemical Processing: PTFE bushings are a preferred choice for the chemical processing industry, where equipment is exposed to corrosive chemicals and harsh environments. They find use in pumps, valves, and pipelines, contributing to the reliability and safety of chemical processes.

4. Food and Beverage: The food processing and packaging industry benefit from PTFE bushings due to their resistance to moisture, chemicals, and low friction properties. They are used in conveyors, filling machines, and other equipment where hygiene and corrosion resistance are vital.

5. Electronics and Electrical: PTFE bushings are used in electrical and electronic applications, including connectors, switches, and insulating components. Their electrical insulating properties and low friction make them suitable for precision electrical components.

6. Medical Devices: In the medical industry, PTFE bushings are employed in various medical devices and laboratory instruments due to their biocompatibility, corrosion resistance, and self-lubricating properties. They are crucial in ensuring the precision and reliability of medical equipment.

7. Renewable Energy: PTFE bushings are used in renewable energy applications, such as wind turbines and solar tracking systems. Their ability to withstand outdoor environments, temperature extremes, and provide low friction contributes to the reliability and efficiency of these systems.

8. Marine and Offshore: In marine and offshore applications, PTFE bushings are found in shipboard equipment, winches, and offshore drilling rigs. Their corrosion resistance and ability to withstand saltwater environments are critical in offshore operations.

9. Industrial Machinery: PTFE bushings play a vital role in various industrial machinery, including conveyor systems, printing machines, and packaging equipment. Their low friction properties contribute to efficient and reliable operation.

10. Rail Transportation: PTFE bushings are used in rail transportation systems, providing smooth and reliable operation in components like train doors, braking systems, and suspension systems.

In summary, PTFE bushings are versatile components used across a diverse range of industries due to their exceptional properties, including low friction, chemical resistance, thermal stability, and electrical insulation. Their ability to reduce wear, energy consumption, and provide reliable performance makes them invaluable in numerous applications, ensuring the efficiency and longevity of mechanical systems in various industries.

The PTFE data sheet is available as a PDF to download below.

Return components within 90 days for a full refund. Please see returns terms and conditions for further information.

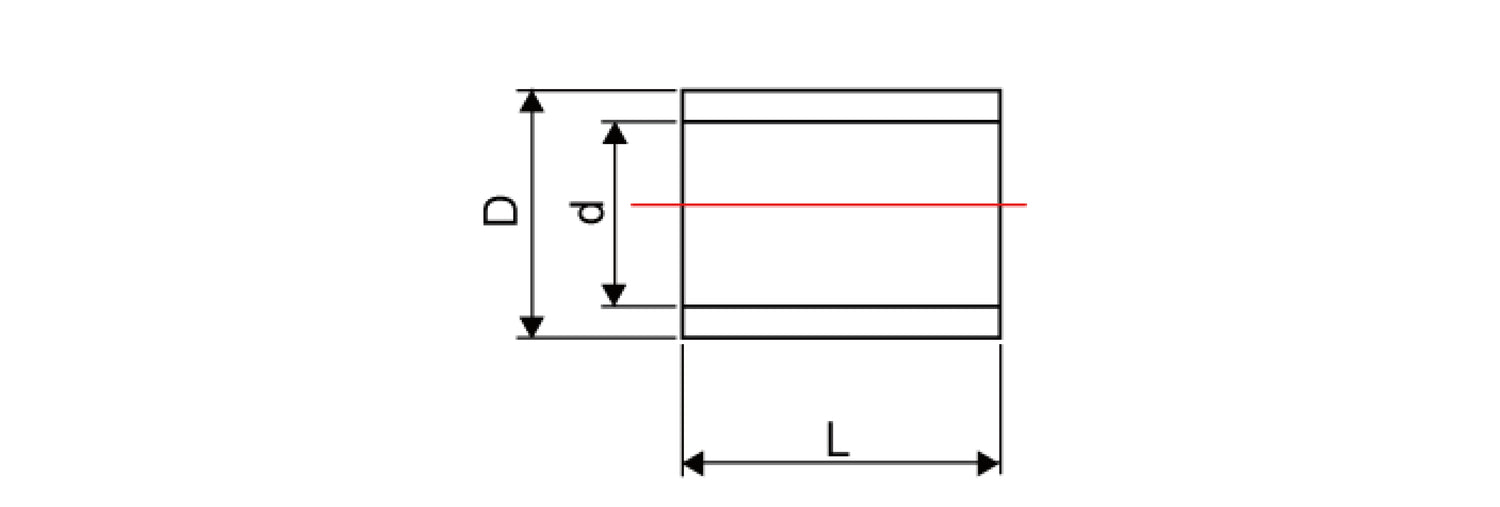

| Inner Diameter (d) (mm) | Outer Diameter (D) (mm) | Length (mm) |

| 1.5 | 4.0 | 2.1 |

| 1.5 | 4.0 | 4.2 |

| 1.5 | 4.0 | 4.4 |

| 2.0 | 5.0 | 4.8 |

| 3.0 | 6.0 | 5.0 |

| 4.0 | 7.0 | 6.0 |

| 5.0 | 8.0 | 6.0 |

| 6.0 | 9.0 | 8.0 |

| 7.0 | 11.0 | 8.0 |

| 8.0 | 12.0 | 8.0 |

| 9.0 | 13.0 | 10.0 |

| 10.0 | 14.0 | 10.0 |

| 15.0 | 20.0 | 30.0 |

| 17.0 | 23.0 | 15.0 |

| 20.0 | 40.0 | 50.5 |

| 22.0 | 28.0 | 20.0 |

| 30.0 | 36.0 | 30.0 |

| 35.2 | 50.5 | 50.0 |

| 65.2 | 85.5 | 70.0 |

| 80.2 | 100.0 | 80.0 |

Dimension Table

Dimensions for PTFE Bushings in all available sizes are shown according to the product drawing above.

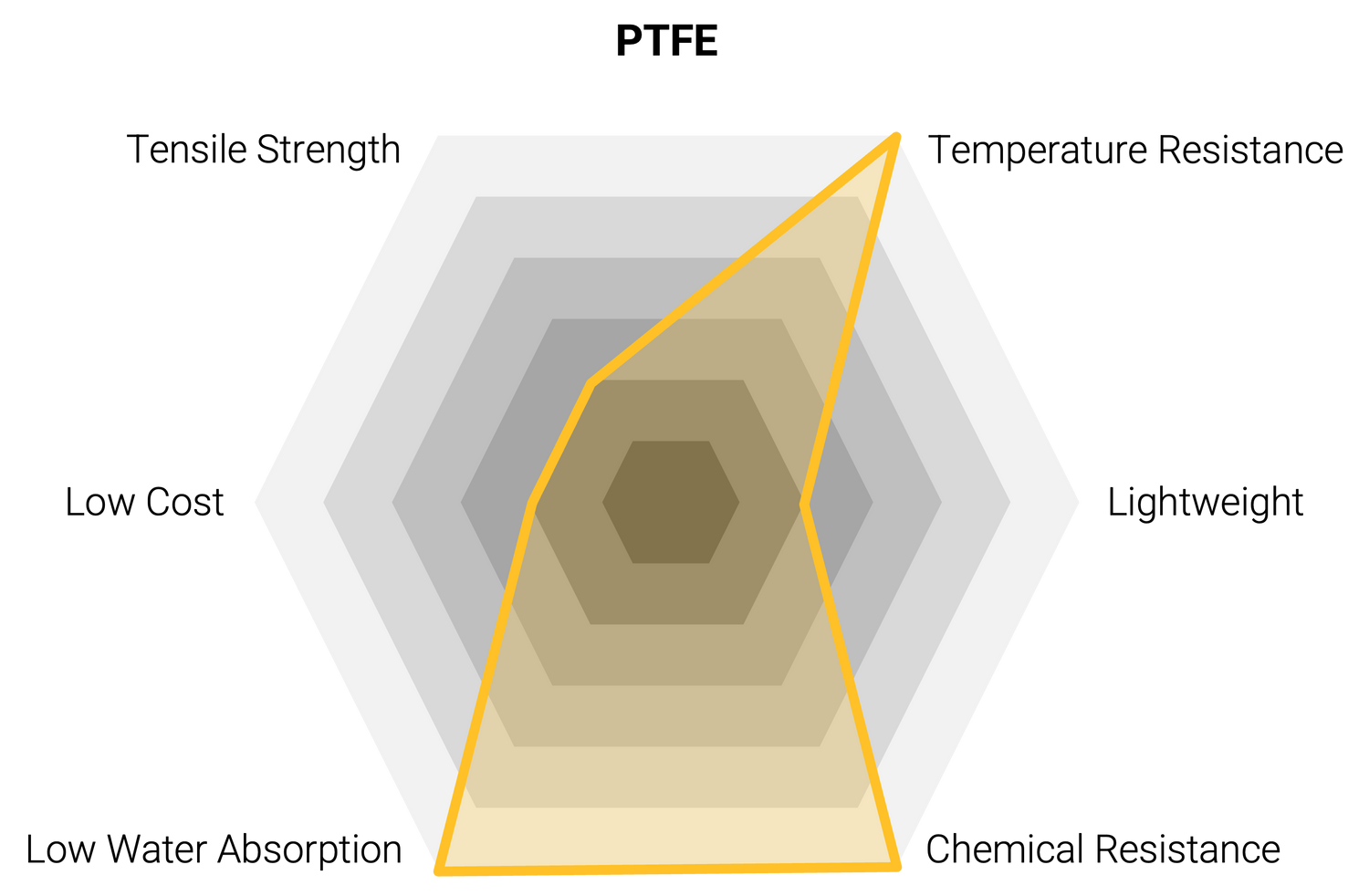

Key Polytetrafluoroethylene (PTFE/Teflon) Properties

Polytetrafluoroethylene (PTFE/Teflon) Datasheet

Follow the link below to view our PTFE data sheet. This includes properties such as mechanical, electrical, thermal and chemical resistance.

Custom Manufacturing

Can't find a component?

We can manufacture components to your specification in any of our performance polymer materials. Click on the link, fill out a short form and you'll receive a competitive, no obligation quote within 24 hours.

PTFE Key Properties

Why Choose High Performance Polymer?

-

50,000+ Fasteners In stock

No long lead times. We have a large range of PEEK fasteners available for express delivery (Dispatched the same day if ordered before 3PM Monday-Thursday).

Fasteners not available for express delivery will display the expected delivery date above the 'add to cart' button.

Manufacturer Direct DistributorWe are a manufacturer direct distributor, this allows us to ensure highly competitive prices and keep our shelves stocked. All of our products are manufactured to the highest standards and exhibit exceptional characteristics.

ISO9001 CertifiedCertified through Quality Veritas. High Performance Polymer conforms to the ISO9001 quality management system. Certificates available on request.

-

Material Certificates

We provide full material traceability and can provide certification confirming material data and batch number, which can be traced back to the manufacturer.

Certificate Of ConformityWe also provide a certificate of conformity on request, confirming the product manufacturing standard and material.