PEEK, or polyether ether ketone, is a thermoplastic polymer known for its exceptional mechanical and chemical properties. It is widely recognised as one of the most robust and durable engineering plastics available, making it sought after in industries requiring materials that can withstand extreme conditions. PEEK is typically supplied in various forms, including sheets, rods, and tubes, allowing manufacturers to create parts for specific applications.

A major reason behind PEEK’s popularity is its impressive combination of characteristics. It has a high melting point, excellent chemical resistance, low thermal expansion, and high tensile strength. Unlike conventional plastics like nylon, polyethylene, or polypropylene, which may become brittle or degrade at higher temperatures, PEEK remains stable under extreme heat, maintaining its mechanical integrity up to 250°C. Additionally, PEEK is known for its resistance to hydrolysis, meaning it can endure long-term exposure to moisture and steam without deteriorating. This makes it superior in environments where other materials might warp, corrode, or break down over time.

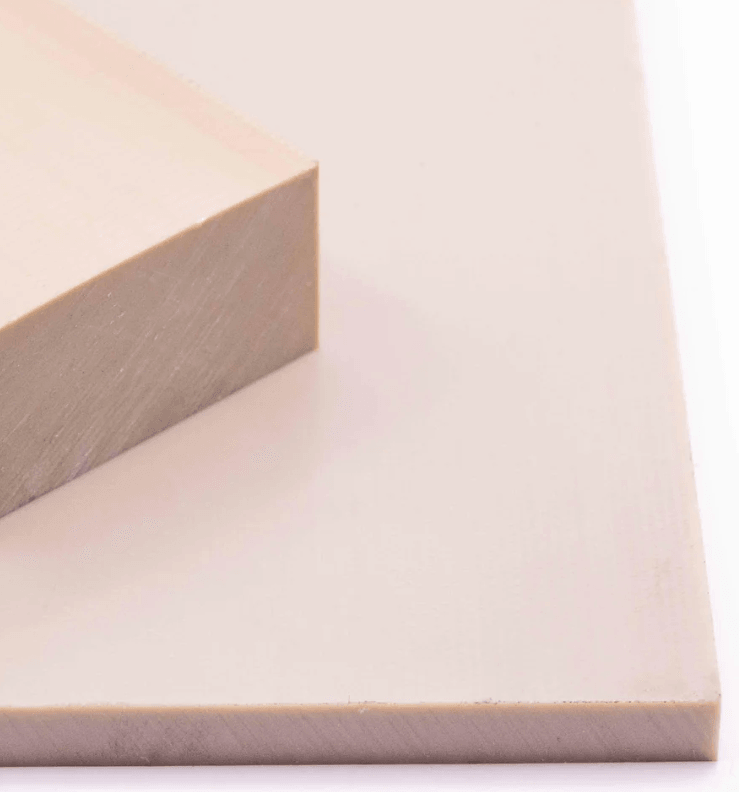

High Performance Polymer offers PEEK sheets in a range of standard sizes to suit various industrial applications, with lengths of 1000mm, 2000mm, and 3000mm, widths of 500mm and 620mm, and thicknesses ranging from 5mm to 80mm. These options ensure that whether you’re looking for material for aerospace components, medical devices, or high-performance seals, you’ll find the right dimensions to meet your needs. Additionally, for specialised projects or applications where unique dimensions are required, we offer custom ‘cut to size’ sheets upon request, tailored precisely to your specifications. If you don’t see the size you need listed, simply get in touch with us—we can manufacture PEEK sheets to meet your exact requirements, ensuring that your project has the material it demands.

One of the primary industries benefiting from PEEK sheet is aerospace. In this industry, materials need to be both lightweight and capable of withstanding extreme temperatures and harsh chemical environments. PEEK fits the bill perfectly. For instance, in aircraft manufacturing, PEEK sheets are often used in components such as structural brackets and cable insulation. These parts are exposed to high temperatures, pressure changes, and corrosive chemicals like hydraulic fluids. Traditional materials like aluminium or steel may be prone to corrosion and require additional coatings, while materials like polycarbonate might soften under high heat. PEEK's natural resilience to these stressors ensures that components maintain their integrity over time, reducing the need for maintenance and replacement, which is critical in industries like aerospace.

The medical field is another sector where PEEK has found extensive application. Medical devices, especially those intended for implantation, require materials that are biocompatible, non-reactive, and durable enough to last within the human body. PEEK meets all of these criteria and is frequently used in spinal implants, orthopaedic devices, and dental applications. Compared to other plastics, such as polyvinyl chloride (PVC) or polyethylene, PEEK exhibits superior strength and wear resistance, making it more reliable in long-term implants. Additionally, PEEK’s radiolucency allows it to be more easily imaged using X-rays, which is particularly useful in diagnostic follow-ups after implantation.

In the oil and gas industry, PEEK's resistance to high pressures and temperatures, combined with its ability to withstand aggressive chemicals like hydrocarbons and amines, makes it a go-to material for downhole and subsea applications. For example, PEEK sheets are commonly used in seals, bushings, and valve components in drilling equipment. Conventional materials such as rubber or metal seals can break down when exposed to the harsh conditions typical of oil extraction. Rubber seals may deteriorate under chemical attack, while metals can corrode over time. PEEK’s inherent strength and chemical inertness significantly prolong the life of these components, reducing downtime and maintenance costs in this demanding industry.

PEEK also plays an important role in the electronics industry, particularly in applications requiring insulative materials. Its excellent dielectric properties and resistance to high temperatures make it ideal for use in connectors, insulators, and semiconductor machinery parts. Materials such as epoxy or polyester, while commonly used in less demanding applications, are inadequate for high-end electronics due to their limited thermal stability and reduced resistance to wear over time. PEEK, however, maintains its properties under continuous thermal stress and mechanical strain, ensuring that electronic components function reliably even in severe operating conditions.

In automotive manufacturing, PEEK sheets are used in various high-temperature, high-stress components such as bearings, seals, and electrical connectors. Traditional materials like polyamides or elastomers can degrade under the intense heat and chemical exposure typical in an engine environment. By contrast, PEEK's resistance to both temperature and chemicals, as well as its low friction coefficient, ensures that parts can endure long-term use without performance degradation. For instance, PEEK is often used in braking systems where high temperatures and wear resistance are critical for safety and performance.

Overall, PEEK stands out because it combines the properties of metal-like strength and durability with the lightweight and versatility of a polymer. This combination makes it irreplaceable in fields like aerospace, medical devices, oil and gas, electronics, and automotive engineering, where no other material would provide the same performance under similar conditions. Unlike inferior materials, which may falter under temperature, pressure, chemical exposure, or mechanical wear, PEEK remains reliable and functional over extended periods. By choosing PEEK, industries not only enhance the performance and longevity of their components but also reduce the long-term costs associated with repairs and replacements.

The advantages of PEEK have made it a valuable resource in demanding engineering applications. It is favoured for its ability to resist degradation where other materials would falter, providing industries with a solution to long-term durability and performance challenges. Whether in aerospace, healthcare, oil drilling, or electronics, PEEK sheets provide an advanced material solution, helping push the boundaries of what modern engineering can achieve.