PTFE Coated A2-70 Stainless Steel Datasheet

Follow the link below to view our PTFE Coated A2-70 Stainless Steel data sheet. This includes properties such as mechanical, electrical, thermal and chemical resistance.

Need Help?

Our team are always happy to help!

Live Chat: Available from the bottom left of your screen.

Email:

sales@highperformancepolymer.com

Phone: +44(0)1865 684080

Material: PTFE Coated A2-70 Stainless Steel

Measurement System: Metric

Drive Type: Hex Socket

Blue

260°C

UL94 V0

All custom manufactured products have a typical lead time of 3-4 weeks.

Please contact us for an exact lead time.

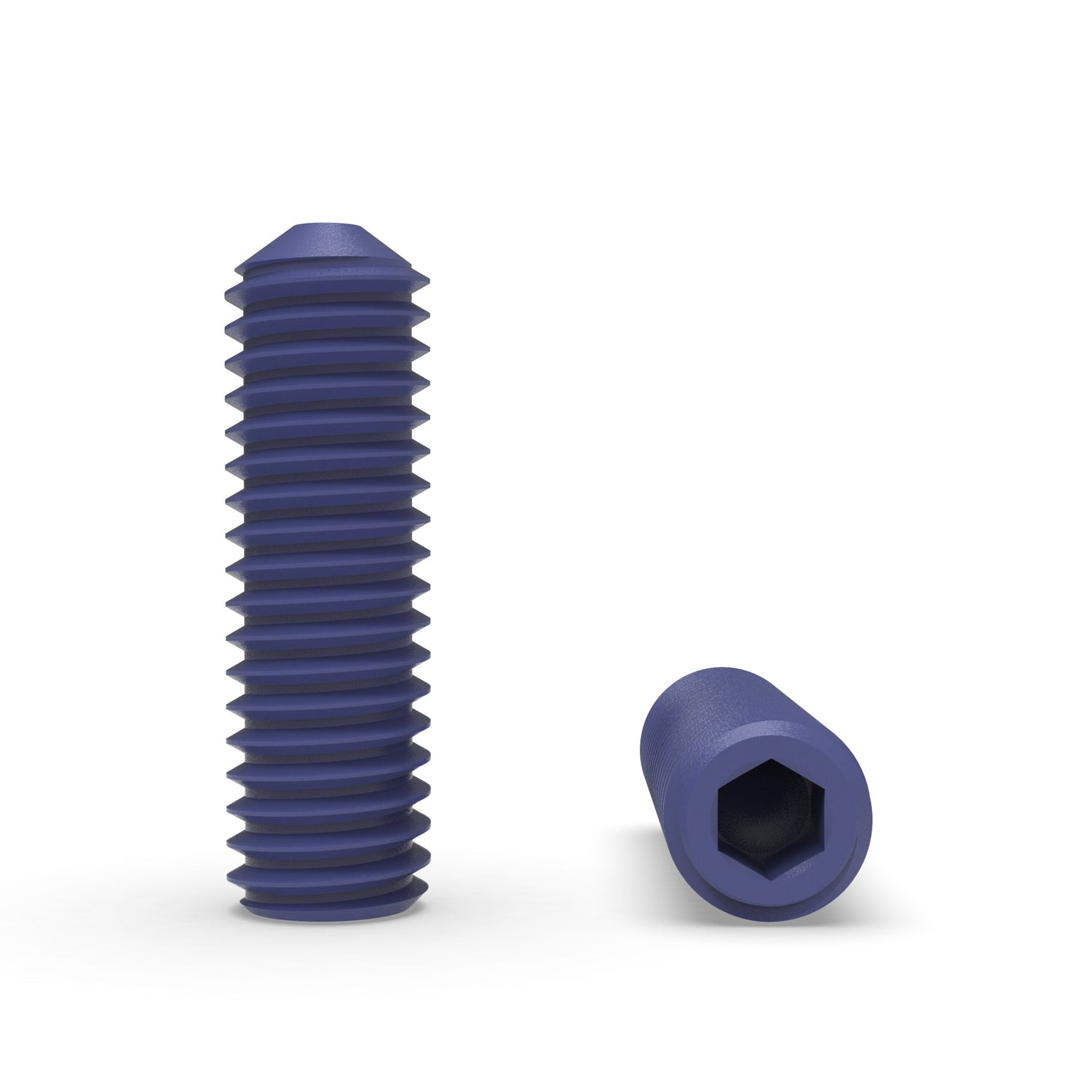

PTFE Coated Stainless Steel Hexagon Socket Grub/Set Screws, available in sizes ranging from M5 to M16 with lengths between 8mm and 80mm. These high-quality set screws feature a recessed hexagonal socket for easy tightening and loosening with an Allen key. Crafted from premium stainless steel and coated with PTFE (Polytetrafluoroethylene), they offer superior corrosion resistance, low friction, and enhanced durability. The PTFE coating provides a non-stick surface and excellent chemical resistance, making these screws ideal for applications in harsh environments, machinery, automotive assembly, and any situation requiring a flush, secure fastening solution.

Metric Size – M5, M6, M8, M10, M12, M14, M16

Length (mm) – 10, 12, 16, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100, 110, 120, 130, 140, 150, 160, 180

PTFE (Polytetrafluoroethylene) coated stainless steel merges the strengths of both materials to form a versatile and highly functional composite. Here's a brief overview of its properties:

Corrosion Resistance: Stainless steel's natural resistance to corrosion, due to its chromium content, is further enhanced by the PTFE coating, providing superior protection against rust, chemicals, and environmental degradation.

Low Friction: PTFE's low coefficient of friction ensures smooth and easy movement. When coated on stainless steel, it minimizes friction between surfaces, preventing wear and increasing durability.

Chemical Inertness: PTFE is chemically inert and resists a wide range of chemicals. This property, when combined with stainless steel, enhances resistance to acids, bases, solvents, and corrosive substances.

Temperature Stability: PTFE maintains its properties across a broad temperature range (-200°C to +260°C). Coating stainless steel with PTFE improves its ability to withstand extreme temperatures without compromising integrity.

Non-Stick Properties: PTFE's excellent non-stick nature prevents substances from adhering to its surface, making it easy to clean and maintain when applied to stainless steel.

Electrical Insulation: PTFE is an effective electrical insulator, preventing electrical conductivity. When coated on stainless steel, it enhances the material's electrical insulation properties.

Biocompatibility: PTFE is biocompatible and inert to biological tissues, making it suitable for medical and pharmaceutical applications. Coating stainless steel with PTFE improves its biocompatibility, reducing the risk of adverse reactions in biological systems.

Hexagon Socket Grub Screws:

A hexagon socket set screw, also known as a grub screw, features a recessed hexagonal socket (Allen socket) at one end and a threaded shaft. It is tightened or loosened using a hex key (Allen key) inserted into the socket. These screws are typically used to secure one object within or against another without a traditional head, making them ideal for applications requiring a flush or concealed fastening solution, such as in machinery, automotive assembly, and furniture construction.

The PTFE Coated A2-70 Stainless Steel data sheet is available as a PDF to download below.

HPP Custom manufacturing enables components to be produced

to your exact specifications - ensuring a precise fit, reliable performance,

and full compatibility with your application. Whether your project is large or small, high or low volume our custom manufacturing service ensures the right material, geometry, and tolerances are met for your specific application.

CNC machining offers precise, repeatable manufacturing for complex parts with tight tolerances. Ideal for high-performance polymers, it ensures accuracy, consistency, and a high-quality finish across both prototypes and production runs.

Injection molding is a cost-effective solution for producing high volumes of polymer parts, both simple and complex with excellent repeatability. It delivers consistent quality and tight tolerances. Ideal for large production runs where precision and uniformity are essential.

Follow the link below to view our PTFE Coated A2-70 Stainless Steel data sheet. This includes properties such as mechanical, electrical, thermal and chemical resistance.