64 Products

Why Are High Tensile Strength Polymer Fasteners Necessary?

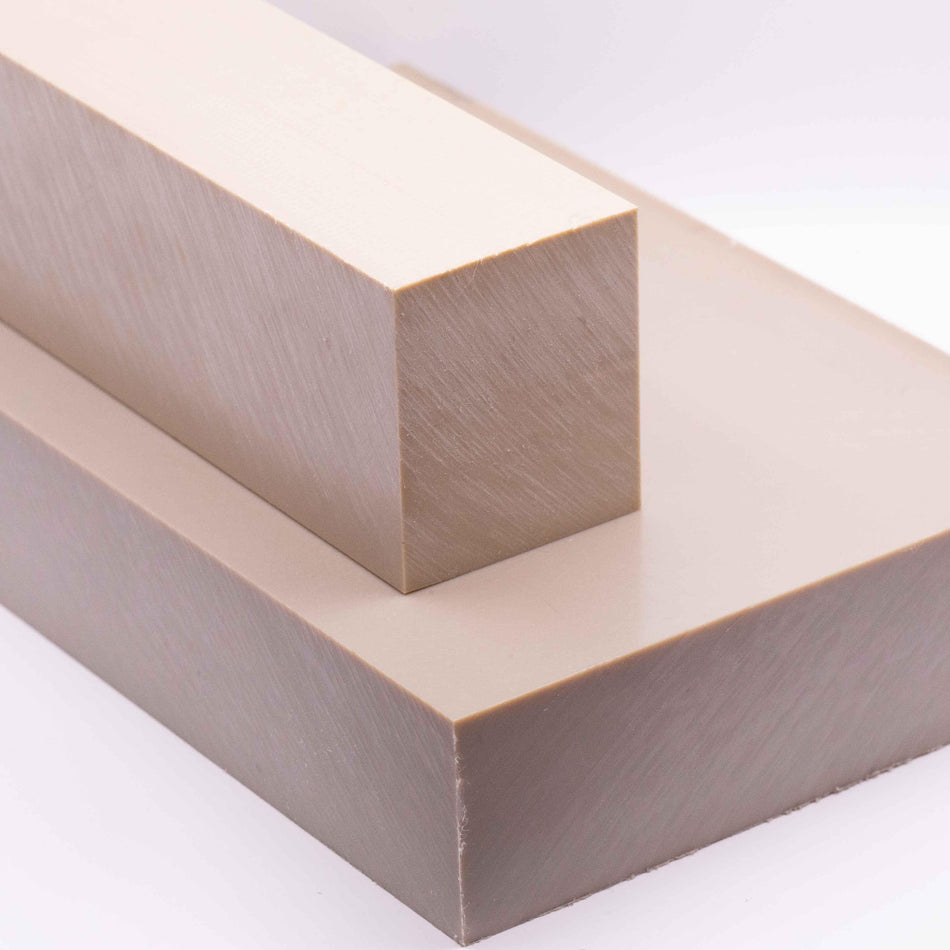

High Tensile Strength Polymer Materials

High Tensile Strength Fastener Applications

How are polymers produced to ensure their high tensile strength?

Why does high-tensile strength matter?

What other properties do high-tensile strength polymers benefit from?

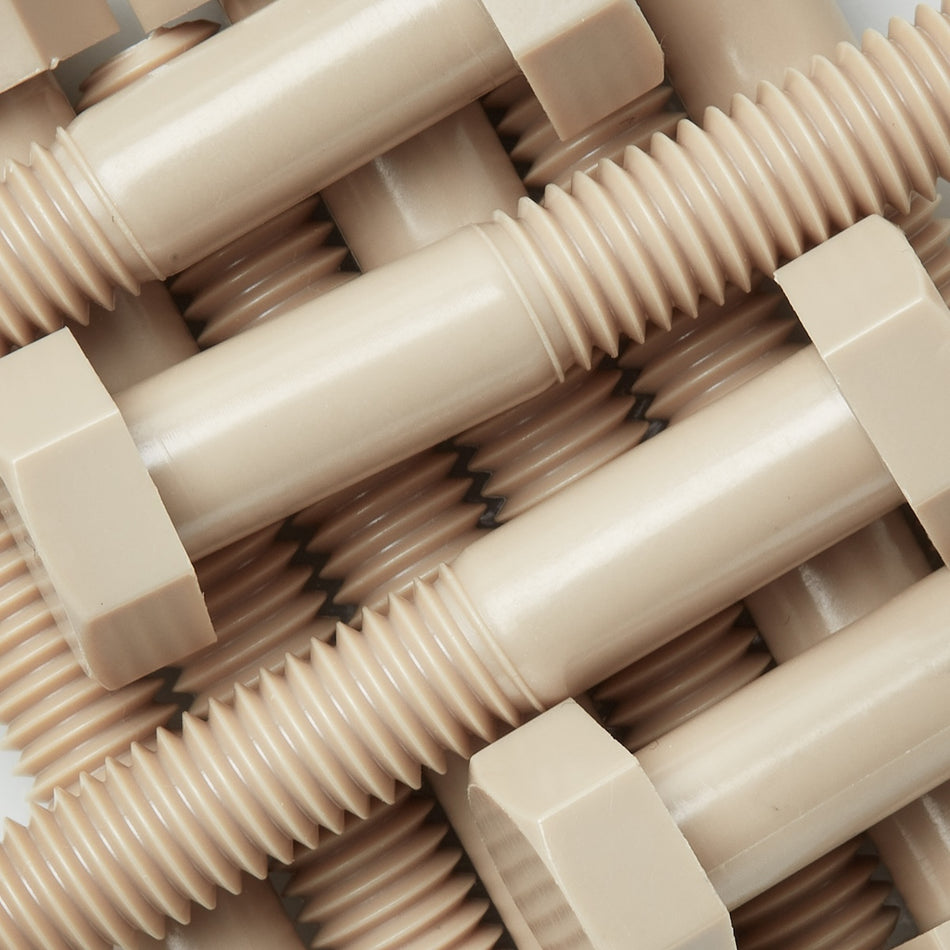

High tensile strength screws, nuts, bolts, washers, and fasteners are fasteners that are designed to have a high resistance to tensile stress, which is the stress that occurs when a force is applied to stretch or elongate a material. High tensile strength fasteners are typically used in applications where high loads or stresses are expected, such as in structural or mechanical engineering, and they are often chosen for their ability to withstand these loads without failing.

High tensile strength fasteners are typically made from materials that have a high tensile strength, such as high-strength steel or certain types of polymer. These materials are able to withstand high loads without stretching or breaking, which makes them suitable for use in high-stress applications.

High tensile strength fasteners are typically used in applications where high loads or stresses are expected, such as in the construction of bridges, buildings, and other structures. They may also be used in the manufacture of machinery and equipment, or in the assembly of mechanical or structural components.

Overall, high tensile strength screws, nuts, bolts, washers, and fasteners are an important component in many applications where high loads or stresses are expected, and they are often chosen for their ability to withstand these loads without failing.